With the Hanover Fair not taking place at all in 2020 and only digitally in 2021, this year exhibitors will once again be presenting themselves on site in the exhibition halls. Among the 2,500 companies taking part in Germany's largest industrial show from May 30 to June 2, Dürr will be welcoming trade fair visitors in Hall 4 (Booth No. D54). At the joint booth with the IT subsidiaries iTAC Software AG and Dualis GmbH IT Solution, visitors can expect a wide range of software solutions for various industries.

Use cases for digital expertise

Dürr is presenting its expertise in digitalization at the Hanover Fair using various use cases:

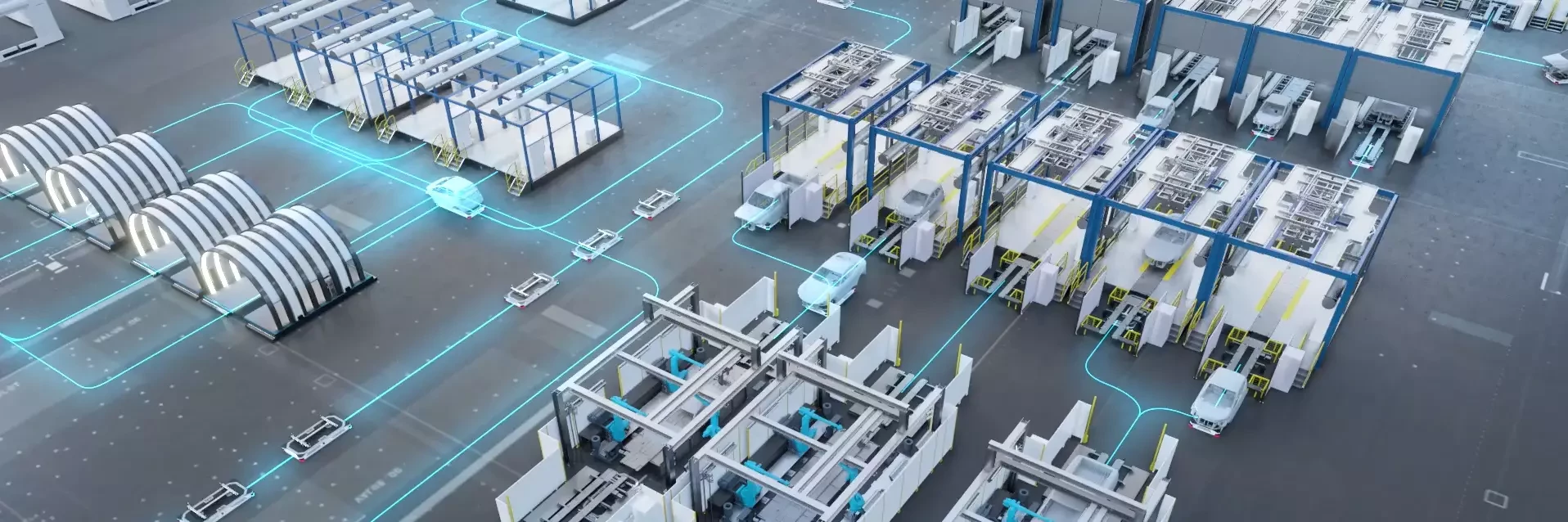

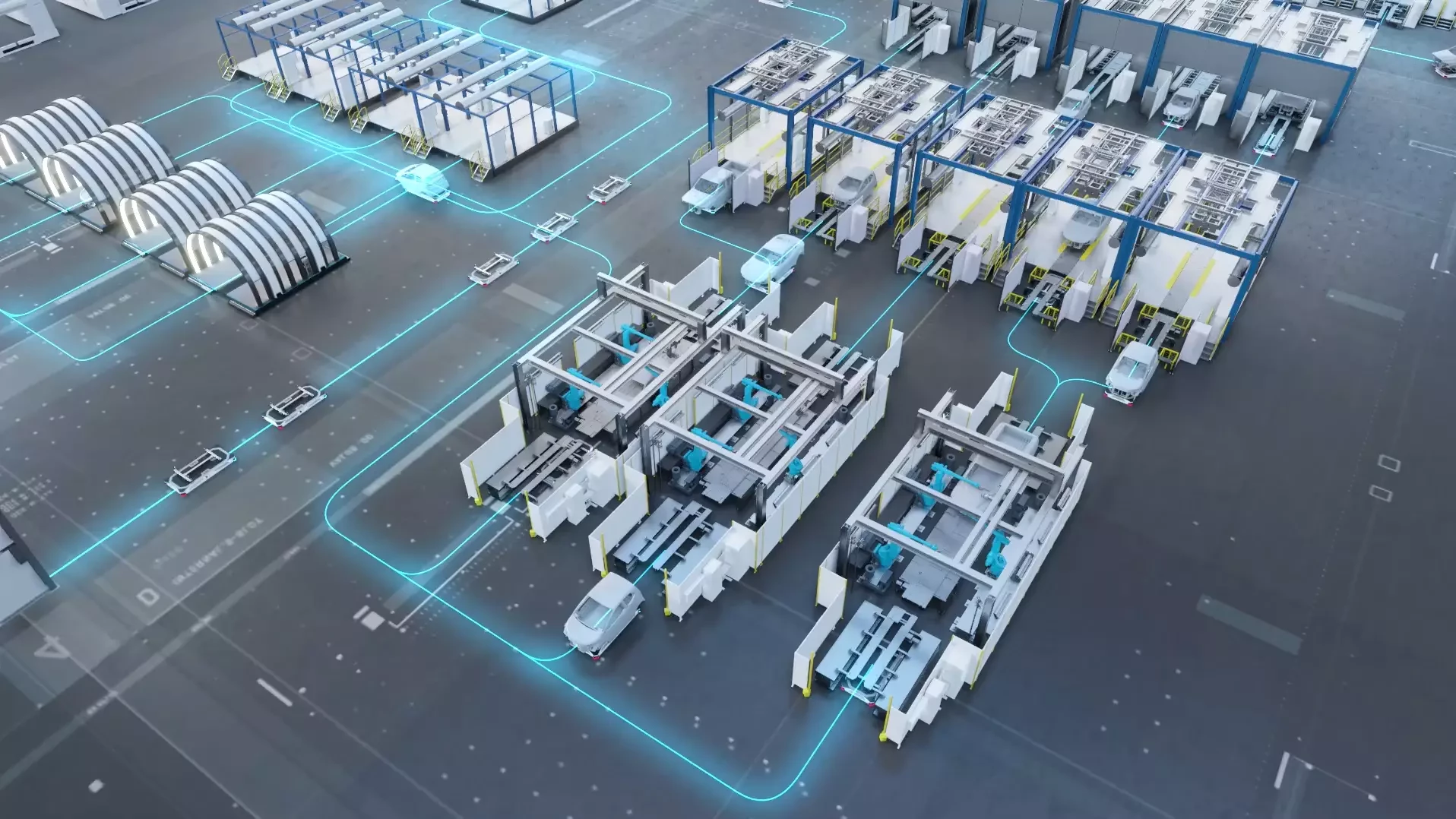

Flexible Manufacturing

The growing variety of products and increasing individualization are pushing conventional line layouts for painting to their limits. That is why the Paint shop of the future needs flexible and scalable production layouts. The use case "Flexible Manufacturing" shows the possibilities of flexible production, based on Dürr's box concept and integrating automated guided vehicles (AGVs). Dürr's control software guides the AGVs to the next process step in each case and ensures efficient utilization of all paint booths.

Holistic Production Control

More transparency and control along the entire value chain: the second use case is aimed at optimizing all manufacturing processes. Dürr's DXQenergy.management will also be presented for the first time in this context. The new product from the DXQ family offers the possibility of central monitoring of energy consumption in a production plant all the way to detailed analysis of individual consumption. The intelligent energy monitoring solution can also be used to display energy flows in production and respective energy costs.

Manufacturing Analytics and Intelligence

"From prevention to prediction" is the motto of the third use case. It showcases the extensive documentation of all available process data in the interaction of products of the DXQanalyze product family. With the help of artificial intelligence (AI) and machine learning, the products analyze collected data and thus detect potential errors or quality defects in real time. This helps prevent machine downtime and determine the most optimal maintenance times possible. The DXQanalyze product family recently won the Industry 4.0 Innovation Award and the Microsoft Intelligent Manufacturing Award.