Manufacturers of metal packaging for personal care, household, food, and pharmaceutical products around the world use systems from Mall + Herlan. The German mechanical engineering company, one of the international technological leaders in this segment, is now taking an usual step. In order to demonstrate the benefits of a new and innovative manufacturing process to its customers, Mall + Herlan, together with its sister company xtracan, has suddenly made the switch to manufacturing metal packaging itself.

VOCs escape along the entire line

The challenges involved in air pollution control for the innovative manufacturing process for monoblock aerosol steel cans are significant: Polluted exhaust air is emitted from almost 30 sources at temperatures that vary widely. In a three-stage process, the aerosol cans are painted or printed from the inside and outside. Unlike paper or plastic packaging, metal does not provide an absorbent substrate. The paint colors therefore contain up to 70 percent solvent. During the burning-in and drying process at temperatures of up to 300 degrees Celsius, the volatile organic compounds (VOCs) contained in the paints and varnishes are released. In addition to the three ovens, the three coating stations, tower storage, and various transport routes are relevant emission sources in aerosol can manufacturing.

Bake-out for reliable removal of deposits (self-cleaning)

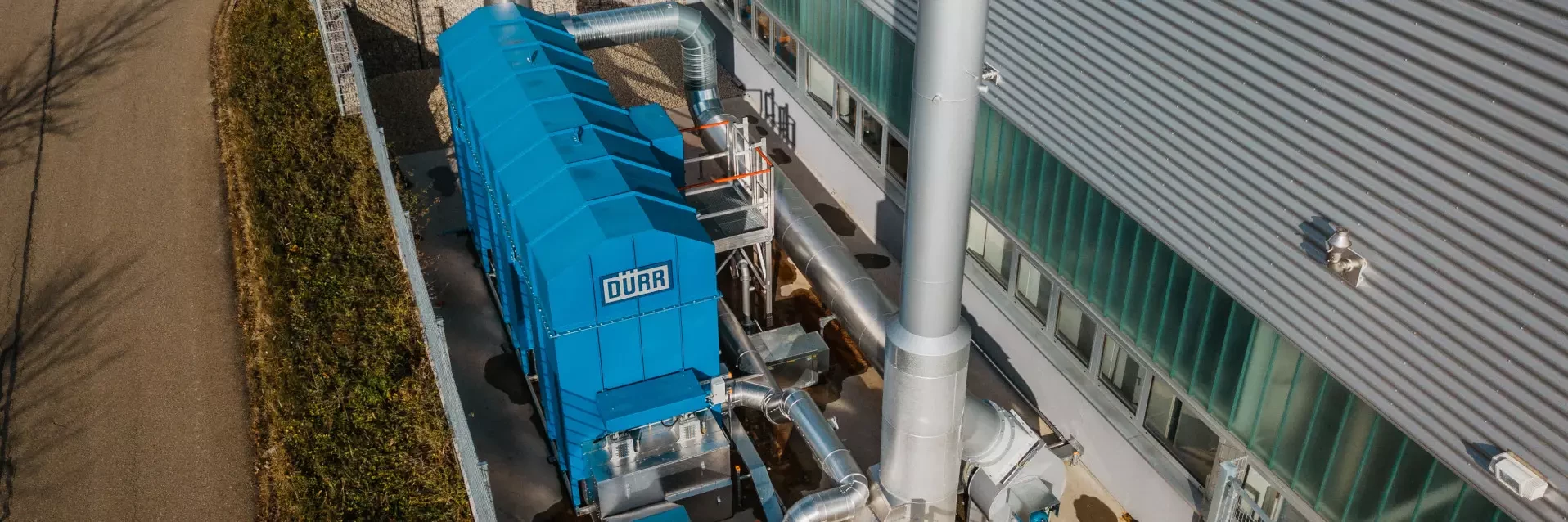

As part of the manufacturing process, there is also a risk of the condensation of critical pollutants, giving rise to solids that can severely clog pipes and the air pollution control system. To purify the exhaust air effectively and, above all, economically, powerful regenerative thermal oxidation (RTO) with a thermal efficiency of up to 97 percent and purification rates approaching 100 percent is used. With an oxidation temperature of up to 850 degrees Celsius, this process even eliminates odor emissions. The Oxi.X RA system type, with over 100 references in this industry segment, also has a fully ceramic internal structure and a special bake-out process.

Heat exchanger as heat accumulator

The Oxi.X RA RTO from Mall + Herlan is rated for a maximum treatment capacity of 11,000 m³/h and pollution loads of 1 to 2 g/m3. In normal operation, which is equivalent to the range from 1.3 to 1.6 g/m3, the highly efficient heat exchanger reduces the operating costs to the absolute minimum through largely autothermal operation. What does this mean? The burner can be switched off completely, and no additional primary energy is needed to operate the air pollution control system. This is possible because the heat exchanger simultaneously acts as a heat accumulator by storing the excess energy in phases with high solvent concentrations. In subsequent phases with low pollutant concentrations, the excessive temperature level – i.e. the stored excess energy – is slowly lowered again and made available. This also saves natural gas. Dürr is increasingly employing this special principle of “thermal buffering” with fluctuating solvent concentrations to “smooth” the resulting fluctuating energy entries.

Environmental protection meets economy

For Mall + Herlan, the Oxi.X RA RTO proved to be the best solution both economically and ecologically. Regenerative thermal oxidation is not only a pioneering and reliable way of ensuring that no official limit values are exceeded, but the high oxidation temperatures and the extremely high degrees of purification achieved as a result mean there is no need for the determination or complex verification of odor emissions in accordance with the new "Technical Instructions on Air Quality Control 2021".