The two paint shops for the Sinotruk subsidiaries Ji’nan Truck and Ji’nan Commercial Vehicle are being built in Laiwu and Zhangqiu in the eastern Chinese province of Shandong. Cabs for various trucks and other commercial vehicles will be painted, including flagships such as Yellow River, SITRAK, and HOWO, with which Sinotruk aims to enter the league of world-class manufacturers. The site in Zhangqiu will also manufacture pickup trucks.

Flexible conveyor technology using AGVs:

Dürr’s automated guided vehicles (AGVs for short) are an important building block for a flexible plant layout, which Sinotruk can expand at a later date, or integrate new models into. EcoProFleet was developed specifically for use in paint shops and is already in use in passenger car production. At Sinotruk, this flexible conveyor technology will now transport truck cabs for the first time. In order to move the heavy loads, the EcoProFleet has been designed with an unladen weight of 850 kg in good proportion with the maximum load capacity of 1,000 kg. The fleet is intelligently controlled by the DXQcontrol software, making sure that all AGVs execute their transport assignments and are permanently on the move. The energy concept with supercap technology also contributes: AGVs are charged within just 1.5 minutes, and at charging points where the AGV is stationary anyway for picking up or setting down the bodies.

Energy efficiency in the PT/EC area:

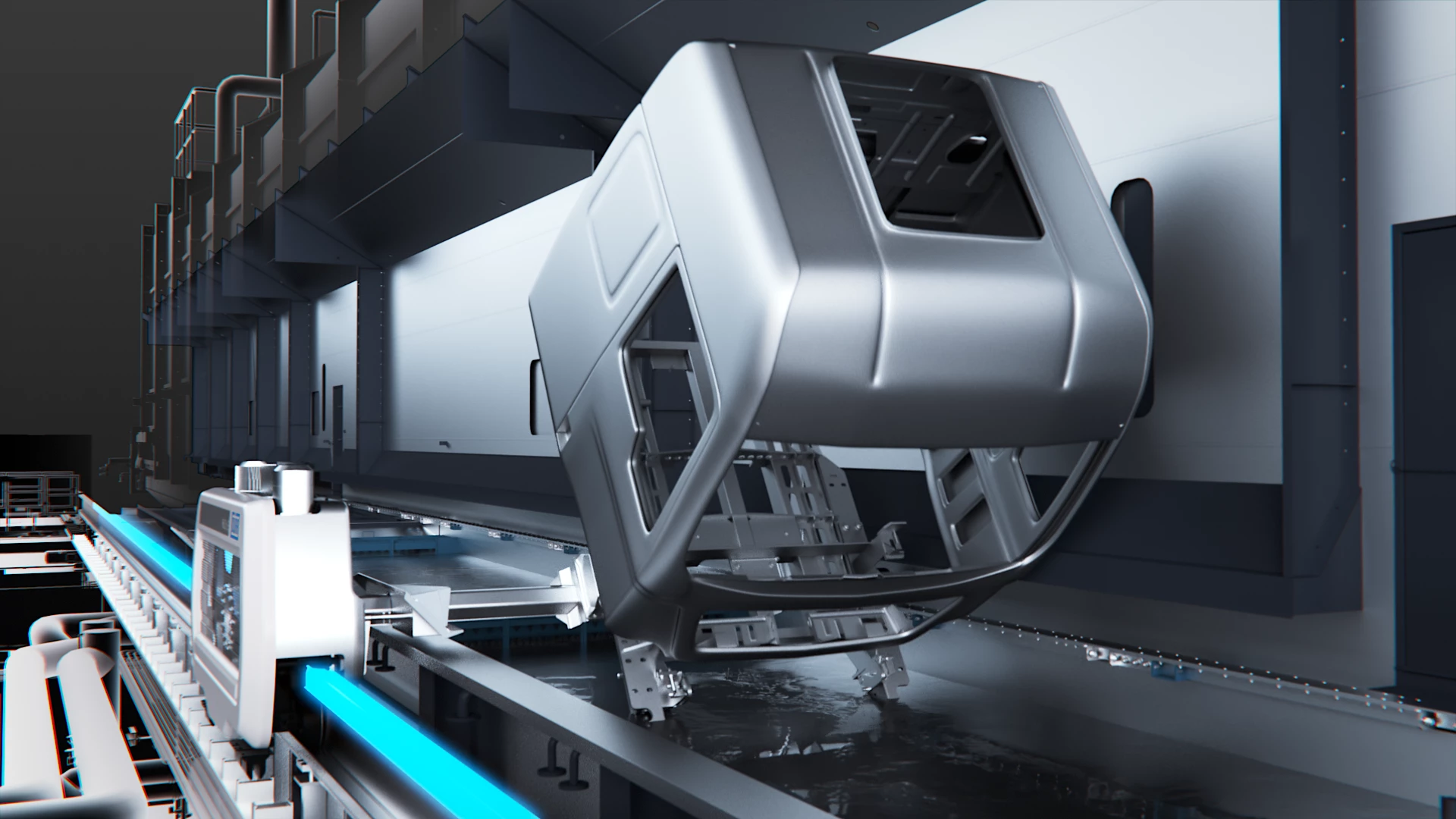

At the beginning of the painting process, the RoDip® rotational dip process provides the optimal prerequisites for subsequent processes. The electric variant RoDip® E permits individual dip curves for pretreatment (PT) and cathodic electrocoating (EC), which optimize the coating quality when dealing with different cab models. With this method, each cab is transported through the complete PT and EC process using a freely programmable trolley. Each trolley has a conveying drive and a rotating drive, which enable horizontal and rotating movements to be controlled independently of each other for each cab. The immersion tanks for the rotational process are smaller than with a traditional pendulum conveyor, which means that less energy and chemicals are required. This saves resources and reduces operating costs.

Fully automated and sustainable application:

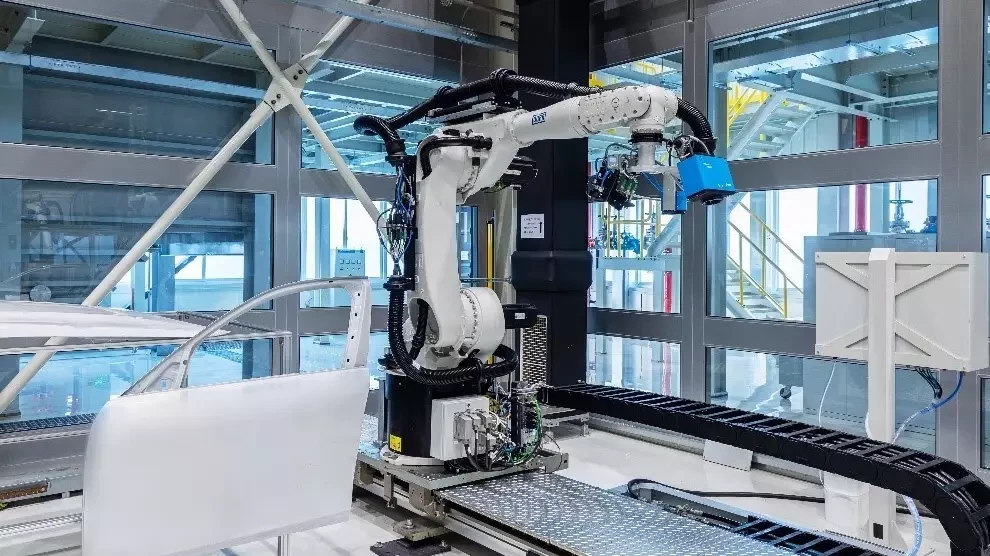

In order to achieve top quality and efficiency in the application, Sinotruk relies on the latest robot technology. In each of the two paint shops, two EcoRS sealing robots from Dürr seal the inner seams and another two apply liquid sound deadener in a fully automatic process. The base coat and clear coat in each paint shop are applied by 19 of the latest generation of EcoRP painting robots, which are equipped with EcoBell3 high rotation atomizers. The state-of-the-art technology allows Sinotruk to achieve the best possible painting results in terms of color shade and flow values, as well as particularly uniform layer thicknesses. At the same time, the Dürr application technology creates less of an impact on the environment thanks to high rotation atomizers with electrostatic charging that are extremely efficient in their material use. With the color change technology and the EcoBell Cleaner D2 for cleaning atomizers, paint loss during color changes and consumption of flushing agent and solvent – and thus VOC emissions – are also minimized.

Environmentally friendly paint separation:

The EcoDry X dry separation system, which doesn’t require water or chemicals, is another technology used in the new Sinotruk paint shops that makes good sense when it comes to energy and economics. The system uses inexpensive cardboard filter boxes to efficiently separate overspray. Another benefit of the technology is how easy it is to use. If necessary, saturated filter boxes can even be replaced during production time.

Automatic and digital quality control:

At the end of the painting process, the body surface is checked at a quality control station. In most paint shops, this is done by means of manual random sampling and data processing. For Sinotruk, Dürr is installing a fully automatic quality control station. Here, a robot follows defined checkpoints on the truck cabs and uses sensors to record data about color variations, surface texture, and layer thickness. This automation saves time compared to manual measurement. This data is transferred to the database and visualized digitally for the worker. This way, the worker always has an eye on the quality.

Outside of the painting process, end-of-line testing technology is also from Dürr. In Laiwu, four x-wheel truck d test stands equipped with high-precision 3D measurement technology are used to measure and adjust the vehicle axis geometry. Dürr meets the specific requirements of the heavy trucks in terms of load carrying capacity, wheelbases, and tracks widths with components specially developed for this area of application. The safety-relevant driver assistance systems of the trucks are precisely adjusted using Dürr test technology. With the modular test stand concept x-DASalign, the sensor technology for the lane departure warning system and the advanced emergency braking system are perfectly aligned in relation to the geometric driving axle of the respective vehicle.

Dürr convinced Sinotruk with the accuracy and efficiency of its testing technology, so the manufacturer also ordered additional test stands for another plant in Zhangqiu in August 2021. The production plant for light trucks will use the x-wheel wheel alignment stand with the latest x-3Dsurface measurement technology and the multifunctional roll, brake and ABS test stand x-road medium truck.

The Sinotruk plants are scheduled to start production in 2021 and 2022, respectively.