Gluing application technology for battery systems

We are entering a new era in the development and manufacturing of battery systems for vehicles, and Dürr’s innovative gluing application technology is leading the way.

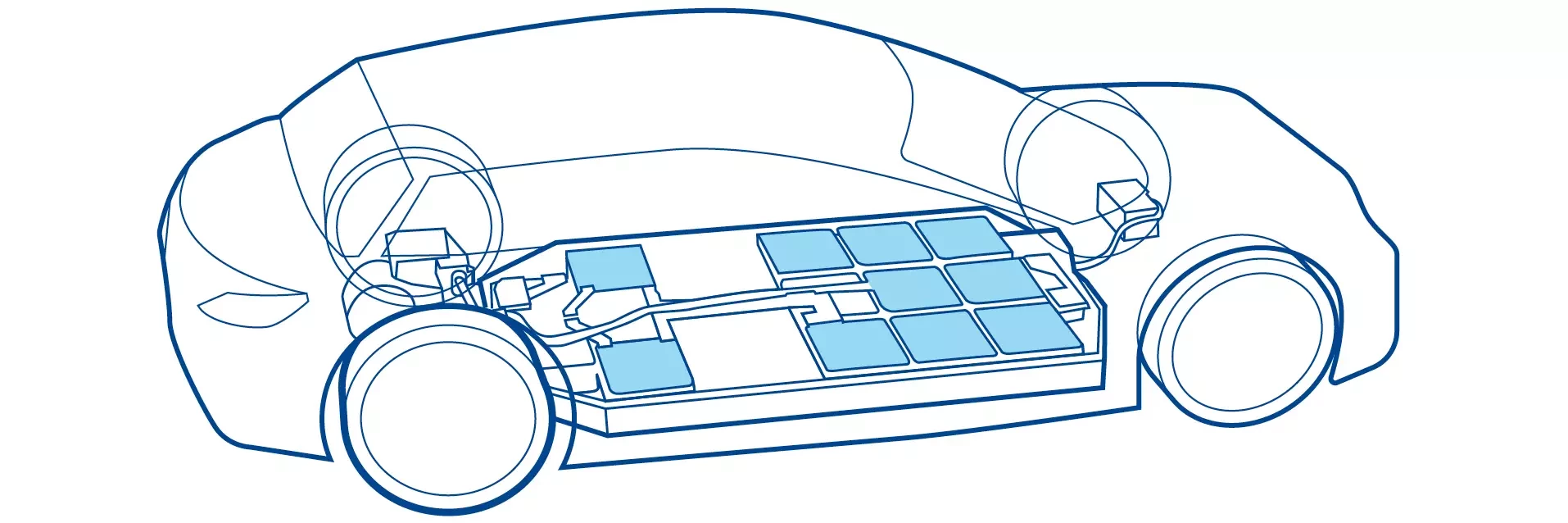

Modern mobility is changing. As alternative drive systems evolve, the spotlight is firmly focused on electric cars and their all-important battery.

Individual battery cells are very sensitive and have to be combined together in one whole battery system. This is where our gluing application technology comes in. A battery system in an electric car can meet all of its varied requirements only if the individual battery cells are perfectly connected. Crash safety is of course the primary concern, but weight and life span also come into play. The superior quality of our application technology provides the answer to these demands. Our technology ensures a precise and even distribution of adhesives and sealing compounds and creates a completely sealed environment with no air inclusions. This means we can better protect the individual cells from vibrations and can guarantee optimal heat conduction. Humidity cannot enter and gases produced cannot escape, which helps to extend to extend the battery’s life span.

Our gluing application is a reflection of our long-standing experience in paint and other application technologies. Our technology ensures that we can successfully apply abrasive materials at a high flow rate and stable temperature.

The modular design of our system allows us to expertly respond to different requirements and the demands of different plant layouts. We offer unheated and temperature-controlled plants to ensure that viscous adhesives and sealing compounds can be easily dispensed. Whatever your need, our broad range of applicators means we’ll have the right one for you. The mixing ratio for two-component adhesives can be adjusted according to the intended area of application.

The modular system also allows the gluing application technology to be used for developments in the lab as well as for building prototypes or large series production. Our process steps are completely reproducible, with the same superior quality guaranteed each time. Processes and components are tested in our on-site test centers under real conditions nearing series production. This is where we also develop customer-specific solutions and continually optimize our processes. For our customers, this means a significant reduction in potential risks before the start of production.

We are supporting the development and manufacturing of battery systems with our versatile and innovative gluing application technology.

- Comprehensive application solutions for bonding battery cells into a battery system

- Battery system requirements (crash safety, sensitivity of individual battery cells, heat conduction during charging, life span, and weight) are given particular attention

- The modular design of our gluing technology ensures increased flexibility

- The system can be expertly adjusted to different process requirements, from the smallest volume processing in the lab to large volume processing as part of mass production