“We at Dürr are very proud of the almost 20-strong team, which has been putting great effort and dedication into this invention since 2008. The innovative strength of our employees is the basis for our company’s success,” says Dr. Jochen Weyrauch, CEO of Dürr AG. “The EcoPaintJet Pro reflects a key focus in our development work: sustainability.”

Improving sustainability

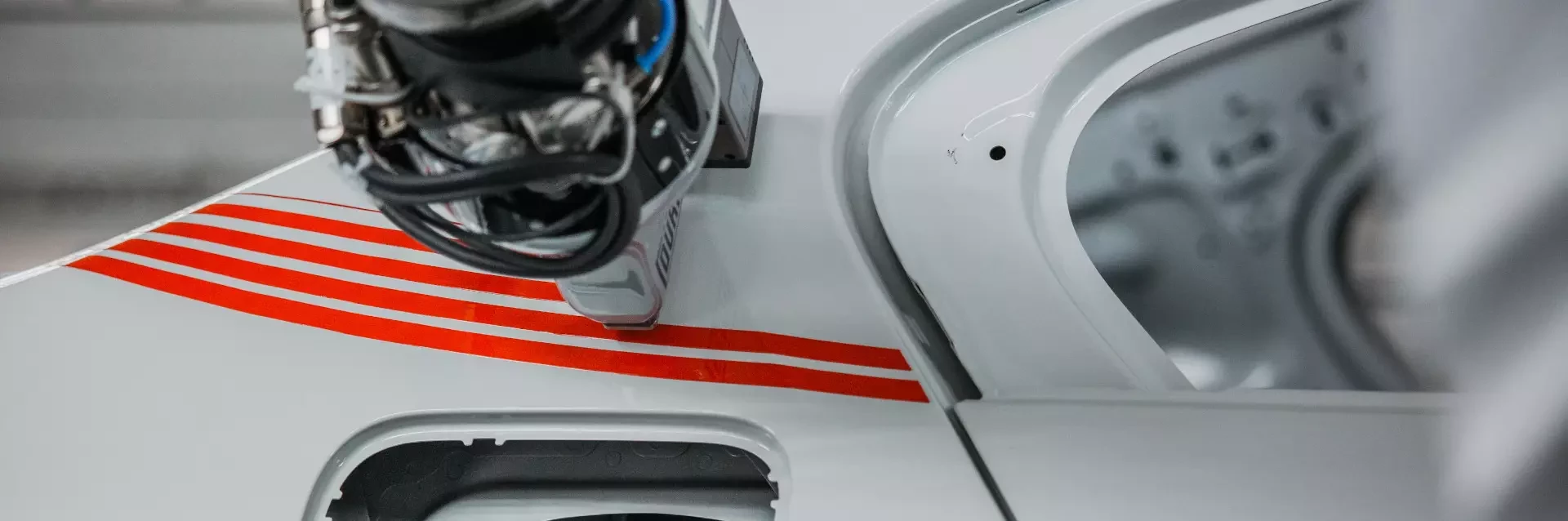

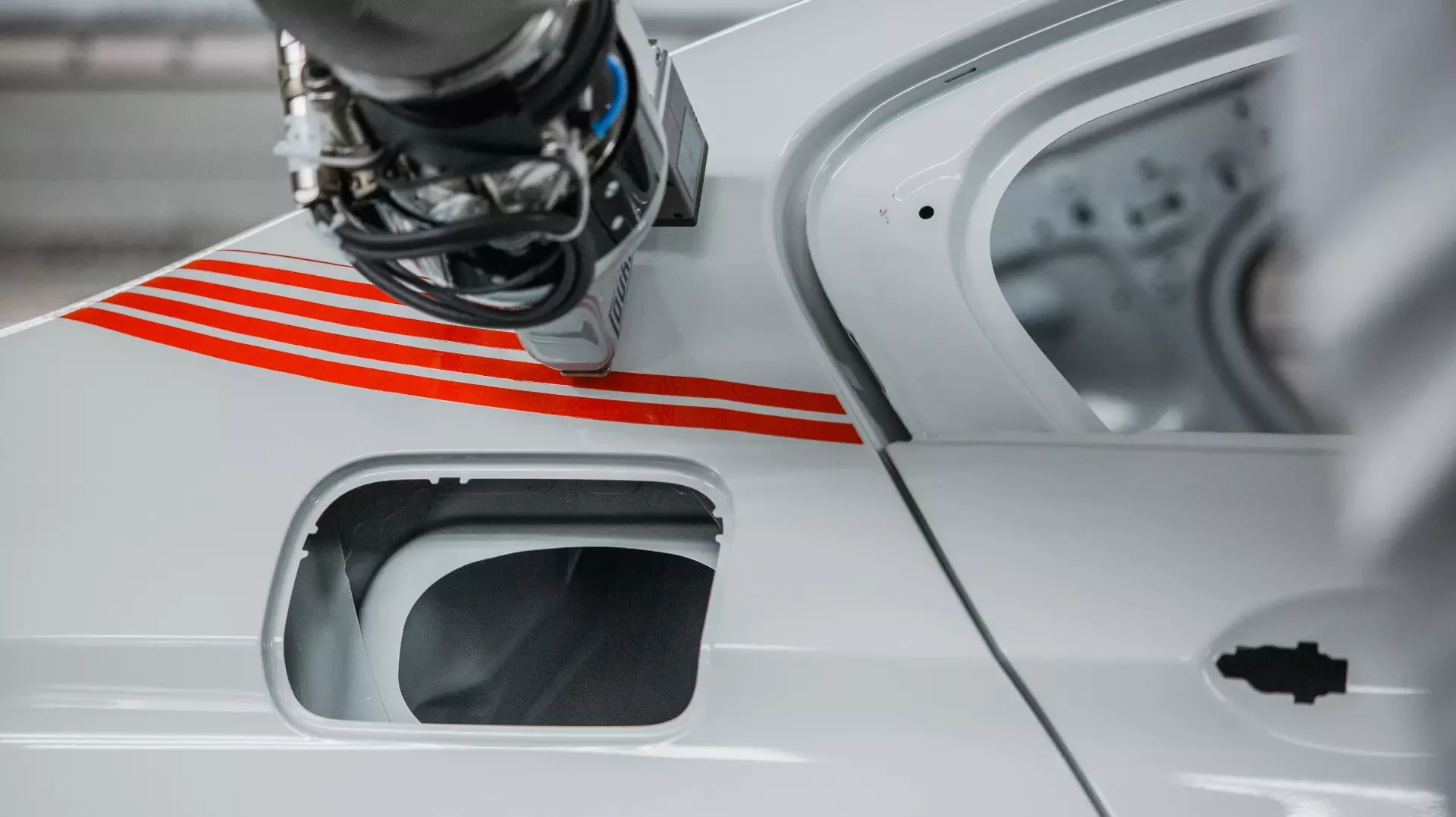

The innovative process shows its strengths not only in terms of possible design diversity and lower production costs. The invention can also improve the sustainability of individual paintshops. Among other things, the DXQ3D.onsite software provides support here: an initial measurement detects and compensates for any inaccuracies in the conveyor system or the body shop. A second sensor mounted on the robot measures the deviation of the car body to be painted from the reference pattern. The robot controller adjusts the painting paths in real time. The speed and tilt angle of the applicator are controlled so that the paint is always applied evenly and there is no overspray and no need for masking. In a standard production line that paints 110,000 car bodies per year, this saves more than 1.5 million square meters of film and 2.2 million meters of masking tape every year plus a lot of manual work. Another advantage is that the new process requires up to 30% less energy than the conventional method.

The Surface Technology Award has been run by the Fraunhofer Institute for Manufacturing Engineering and Automation since 2012. For the top position, technologies must convince in the criteria innovation leap, sustainability, enabler technology and industrial feasibility.

Permanent guest at awards ceremonies

Thanks to its innovative strength, the EcoPaintJet Pro has already won several prizes in Germany and abroad - including the German Innovation Award. It was also recently a finalist for the prestigious European Inventor Award, which is organized by the European Patent Office.