Dürr has confirmed its position as a market leader in China with two orders for BMW. In Dadong district in Shenyang, BMW has been operating a Dürr paint shop since 2016 and is now increasing its capacity. In Tiexi district in Shenyang, where BMW has already been using Dürr painting technology since 2013, Dürr will build a further paint shop in a new manufacturing facility. In addition, BMW is already planning a second expansion stage in Tiexi and has agreed the future expansion with Dürr. An agreement has also been made with Dürr on the construction of a paint shop in Europe, with a new BMW plant in Debrecen (Hungary).

“In Dürr, BMW has chosen an experienced general contractor for its investments in the manufacturing facilities in Asia and Europe who can deliver innovative technology for the entire painting process and whose solutions make a contribution to sustainable production,” says Dr. Jochen Weyrauch, Chairman of the Board of Dürr Systems AG, in summing up the current orders. “BMW will get three paint shops that set standards for sustainability, flexibility, and quality.”

Dürr will deliver proven technology and the latest innovations packaged in a convincing plant concept at all three sites. Successful products like the patented RoDip® rotational dip process from Dürr will create outstanding conditions in pretreatment and cathodic electrocoating for the subsequent paint application.

Efficient use of resources, from application to drying

The application step of BMW’s Integrated Painting Process (IPP) in all three paint shops will be handled by Dürr painting robots with high-rotation atomizers of the type EcoBell3. A total of 165 painting robots and 90 sealing robots from Dürr will paint and seal the BMW models in the three plants. Integrated supply systems for the paints and thick matter used as well as a paint mixing room will ensure an efficient paint supply in the standard color palette. Dürr will install the EcoSupply P system for supplying special colors. Pigging systems will transport the special colors to the paint booth in hoses – with almost zero losses. The coordinated application technology will minimize paint and detergent consumption and ensure fast color changes.

BMW will use sustainable, resource-saving technology throughout the three new paint shops. The Dürr products for paint separation – EcoDryScrubber, in China and EcoDry X in Hungary – boast strong environmental credentials. EcoDryScrubber is based on paint separation using limestone powder, while EcoDry X uses cardboard filter boxes as a separating agent. The Dürr technology thus does not involve any polluting methods that use a mixture of water and chemicals. The recirculation of up to 95% of the air used in Dürr's separation processes also enables a 60% reduction in energy consumption in the paint booth.

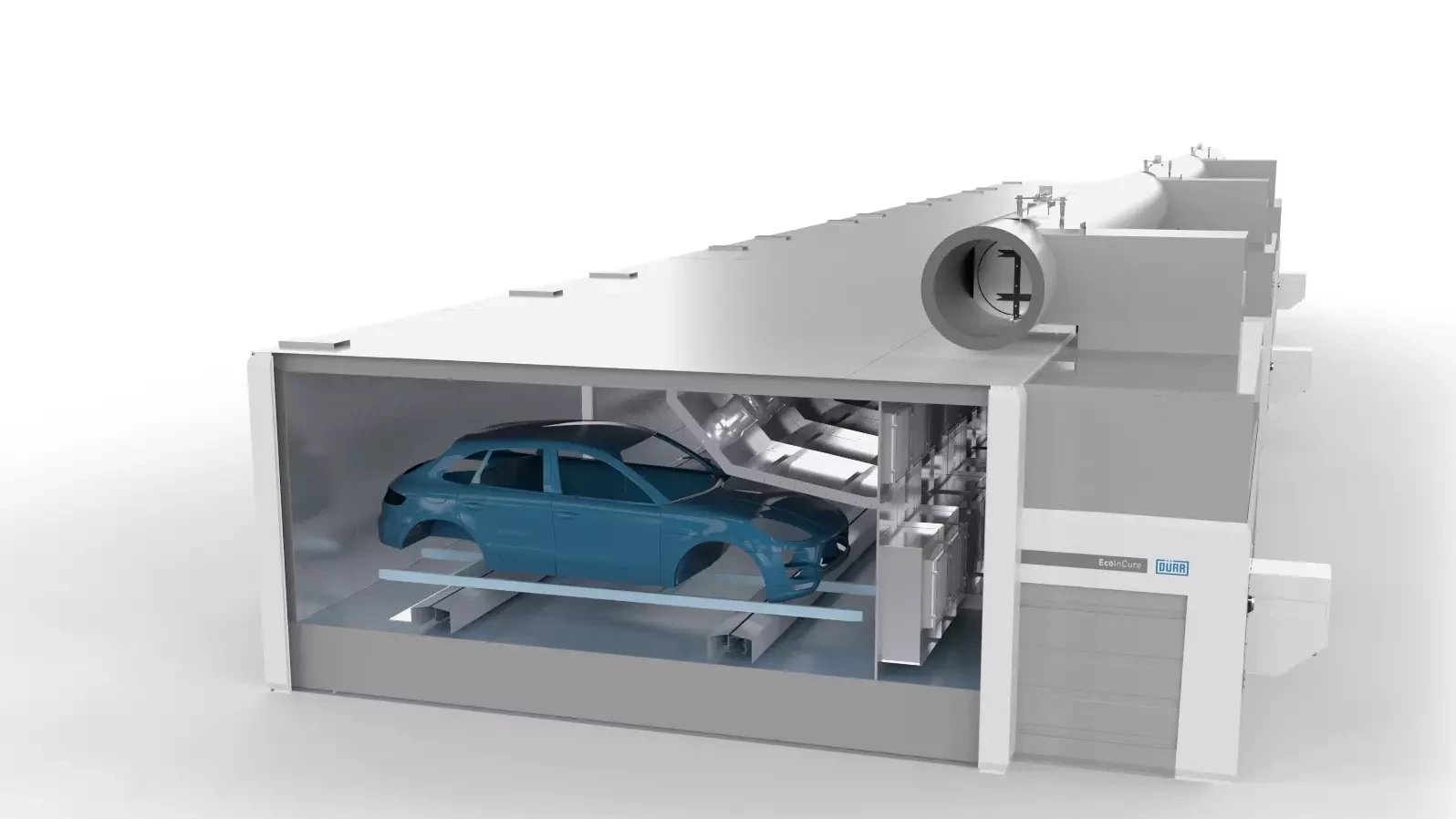

The EcoInCure oven, which will be used in the new plant in Tiexi as well as in Debrecen in the top coat section, will additionally boost the energy efficiency of the plant. The oven’s exhaust air can be purified using just one afterburning system of the type Ecopure® TAR. A comparable double oven with conventional continuous flow technology would need two air pollution control systems. This reduces the amount of fresh air required, and thus the energy demand. EcoInCure uses a new technology for drying: the air flowing in through the opening for the windshield heats the body parts from the inside out, resulting in particularly uniform and fast drying of the bodies – even special body shapes like those of electric vehicles.

Compact and scalable layouts

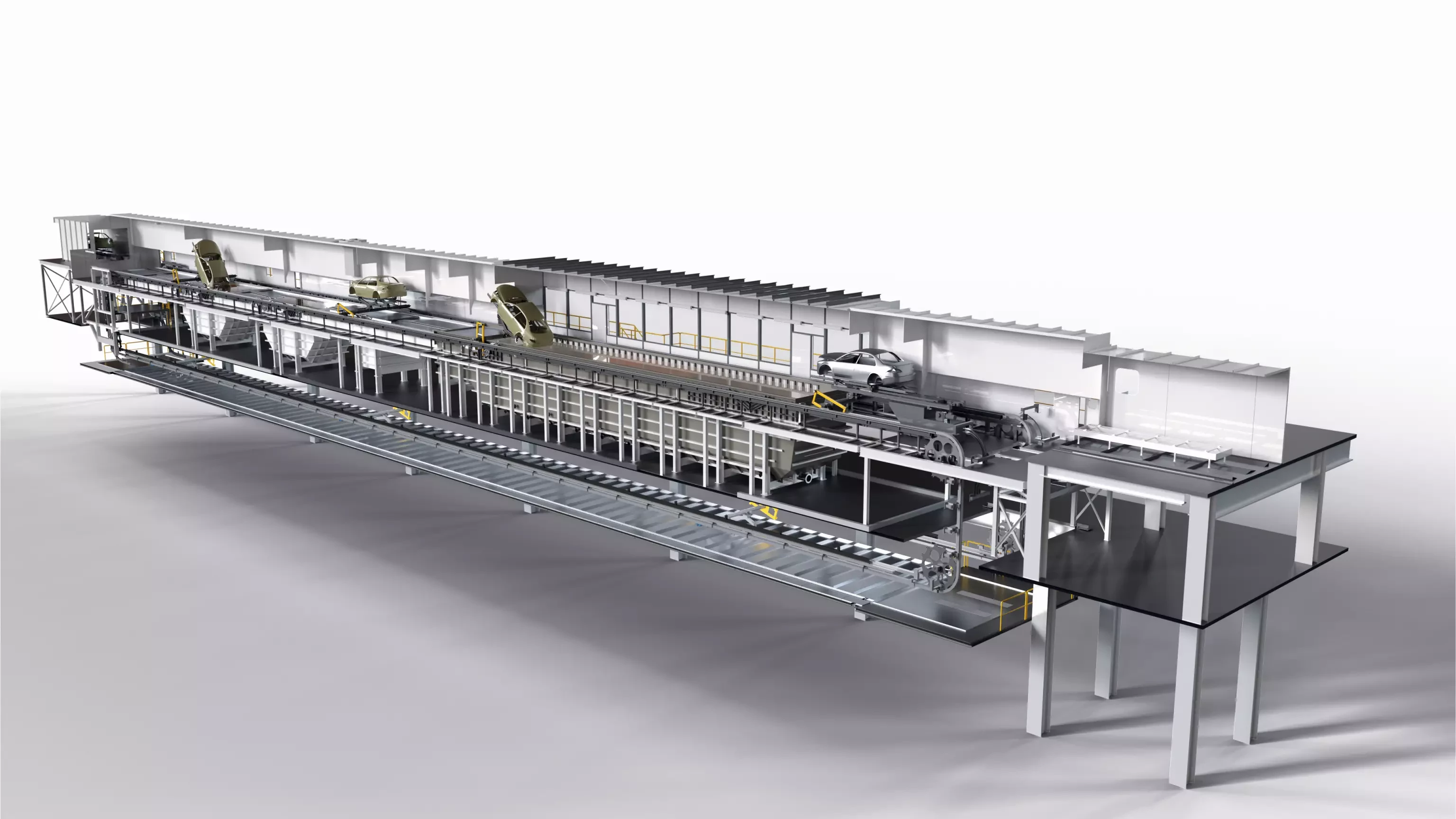

BMW is using an integrated skidless conveyor system for the first time in the new plants in Debrecen and Tiexi. Here, the bodies are transported through the plants exclusively on traverses. This means that no space is required for return transport of the skids and there is no need to clean skids in the top coat section. The end result is compact and scalable layouts.