Plastic painting – Process and product expertise from a single source

When it comes to painting plastic add-on parts, Dürr has both the expertise and the portfolio required. Combine the two and you get optimized, customized solutions. We supply turnkey plants for the entire process from a single source.

Our in-house expertise covers everything from cleaning and activation through application and overspray separation to air pollution control. We can plan and implement individual process steps or full turnkey plants – always based on efficient, proven systems.

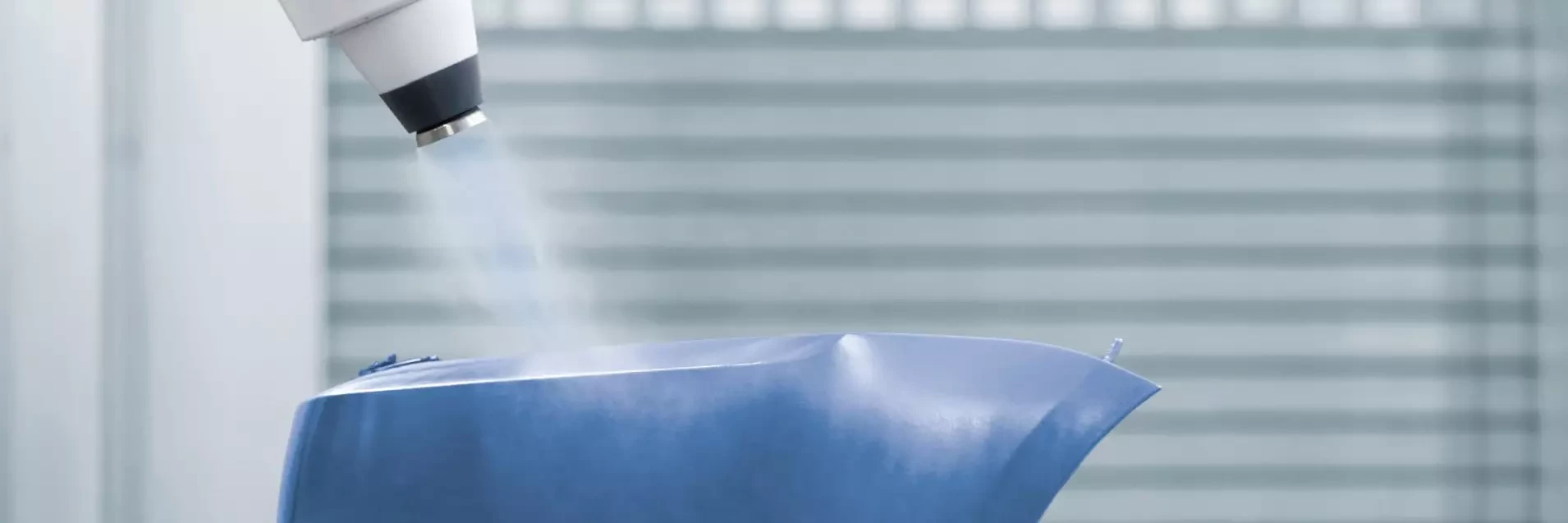

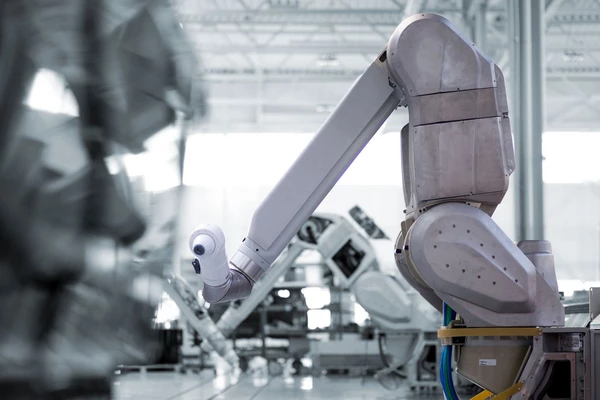

In the plastic painting process we use cleaning and pretreatment technologies such as powerwash (with degreasing, rinsing and blowing zones), space-saving and energy-saving CO2 cleaning and flame treatment. We manufacture application technology, paint supply and conveyor systems, spray booths and ovens in our own production facilities around the world.

For top-quality painting results, Dürr configures all the products, technologies and processes to meet individual customer requirements, with or without primer or using 3-wet or wet-on-wet processes. With cutting-edge control systems and high-performance air pollution control, our offering really is the whole package.

Our plastic painting portfolio includes

- Tailored greenfield and brownfield plants

- Comprehensive process expertise and high-quality technologies:

- CFD simulation and initial concept planning

- Pretreatment and corrosion prevention

- Spray booths and robot application systems

- Oven systems

- Conveyor systems

- High-performance automatic control and digital connection

- Air pollution control

- Professional implementation and start-up management

- Spare parts service, inspection and maintenance

- Service locations worldwide