Paint shop of the future

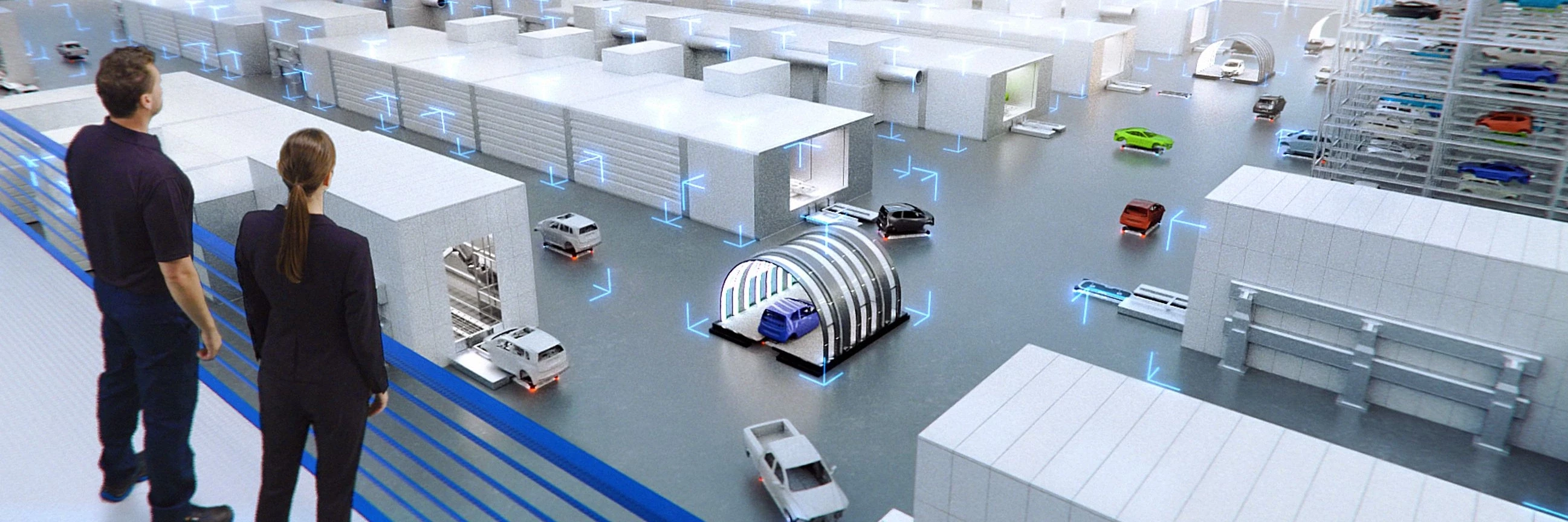

Scalability and flexibility have become central requirements within automotive industry production processes today. Dürr's paint shop of the future moves beyond boundaries and opens up new potential in automotive manufacturing.

Dürr’s paint shop of the future breaks away from traditional layouts in automotive production. A modular concept, in combination with intelligent IIoT solutions, allows production volumes to be easily adapted for all scenarios.

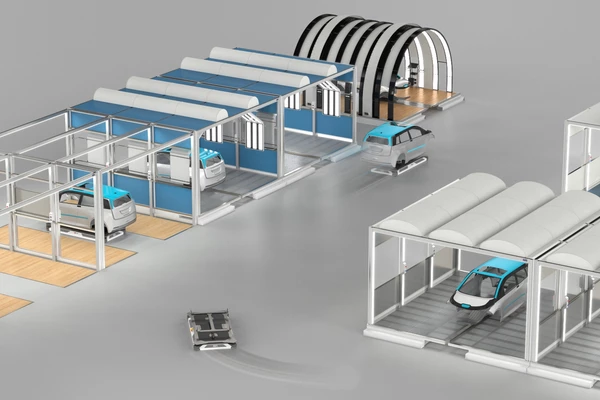

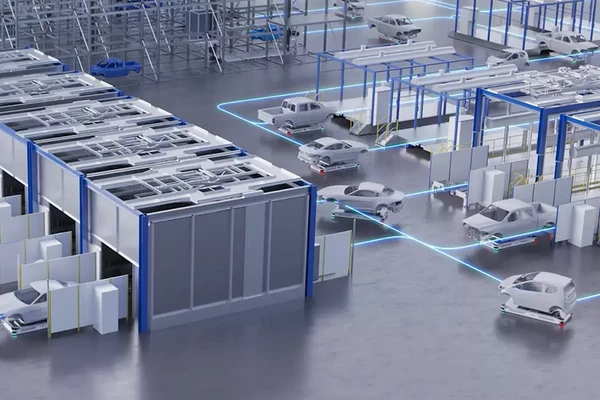

The key idea is to split up the line concept into boxes. The extent may vary according to specific cases and can affect either selected areas or the complete top coat and workplace area. Combined with a central high-bay storage system, this results in a highly flexible and scalable layout.

In this way, every customer’s request can be fulfilled. Whether you want to produce small or large quantities or a large variety of body models, Dürr's paint shop of the future offers the flexibility to do so. New body models, such as electric vehicle models, can be more easily and quickly integrated into the existing system thanks to the independent boxes.

The box-based layout enables individual cycle times, even allowing different applications and quality requirements to be realized for different vehicle types.

Your advantages

- Demand-oriented process times instead of fixed-cycle times

- Easy integration of new car models

- Easy integration of new, specialized processes

- Easier scalable capacity compared to the line concept

- Assignment of single boxes for special tasks possible, e.g. teaching of application technology for new car bodies, while production is continuing in other boxes

- Higher availability: Production continues even at standstill of individual boxes