Pump solutions for any kind of application

Dürr has developed several pump models to do justice to the demanding and highly diverse paint supply requirements of the industrial sector. Their different drives and methods of operation make these pumps suitable for materials with very varied properties, and for an extremely broad range of possible uses.

Our Pumps

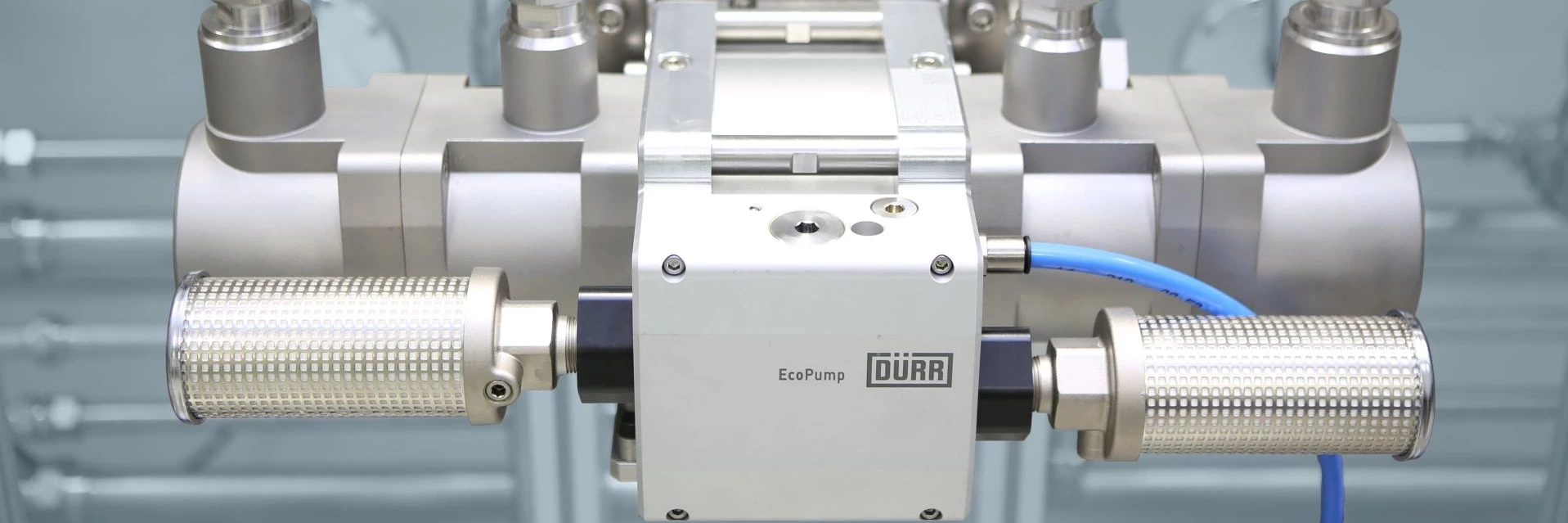

The EcoPump HP is an air driven horizontal piston pump. Performance and durability are further distinguishing characteristics in order to meet the highest demands. With a concealed shaft seal this EcoPump HP is primarily designed for paint circulation systems as well as fluid transfer and supply. A horizontal two piston design guarantees equal thrust on both strokes and a rapid pump change-over with a quick release valve for reduced surge. Its modular design enables easy maintenance. Typically handled fluids are water and solvent borne paints, varnishes, enamels and lacquers.

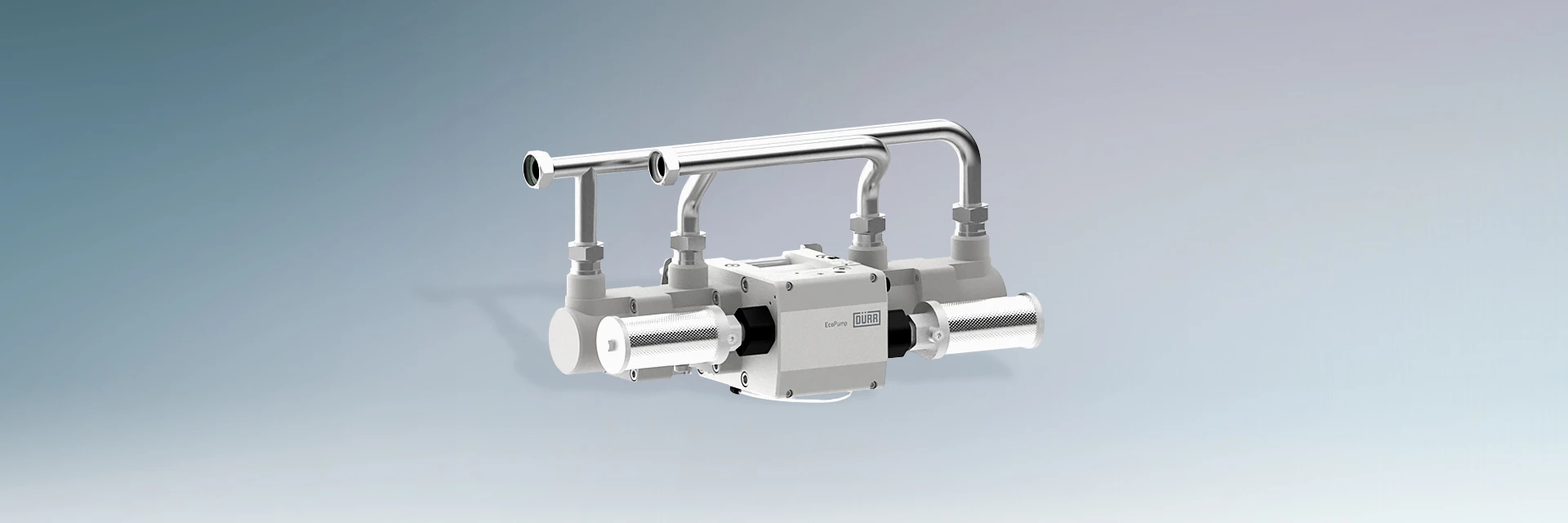

The EcoPump HPE is a horizontal piston pump with an electric drive to achieve superior performance with lower operating costs. Durability and reliability are further distinguishing characteristics in order to meet the highest demands. With a concealed shaft seal the EcoPump HPE is primarily designed for paint circulation systems as well as fluid transfer and supply. A horizontal two piston design guarantees equal thrust on both strokes. Its modular design enables easy maintenance. Typically handled fluids include water and solvent borne paints, varnishes, enamels and lacquers. The EcoPump HPE has been tested according to DIN EN 12162.

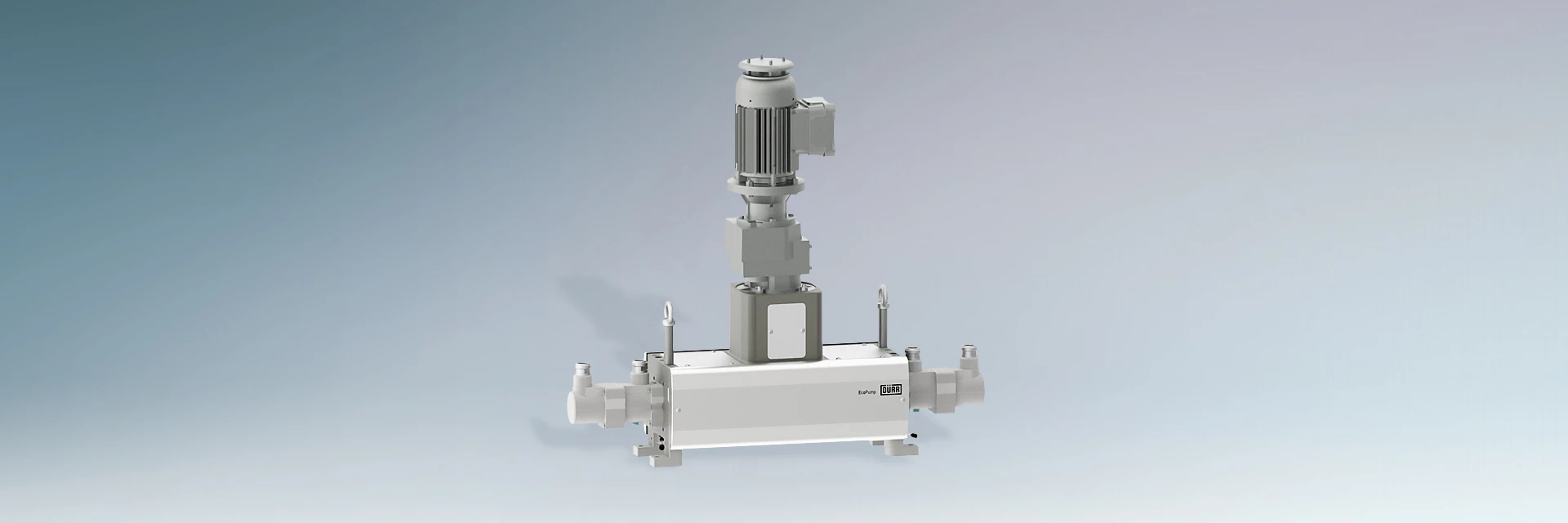

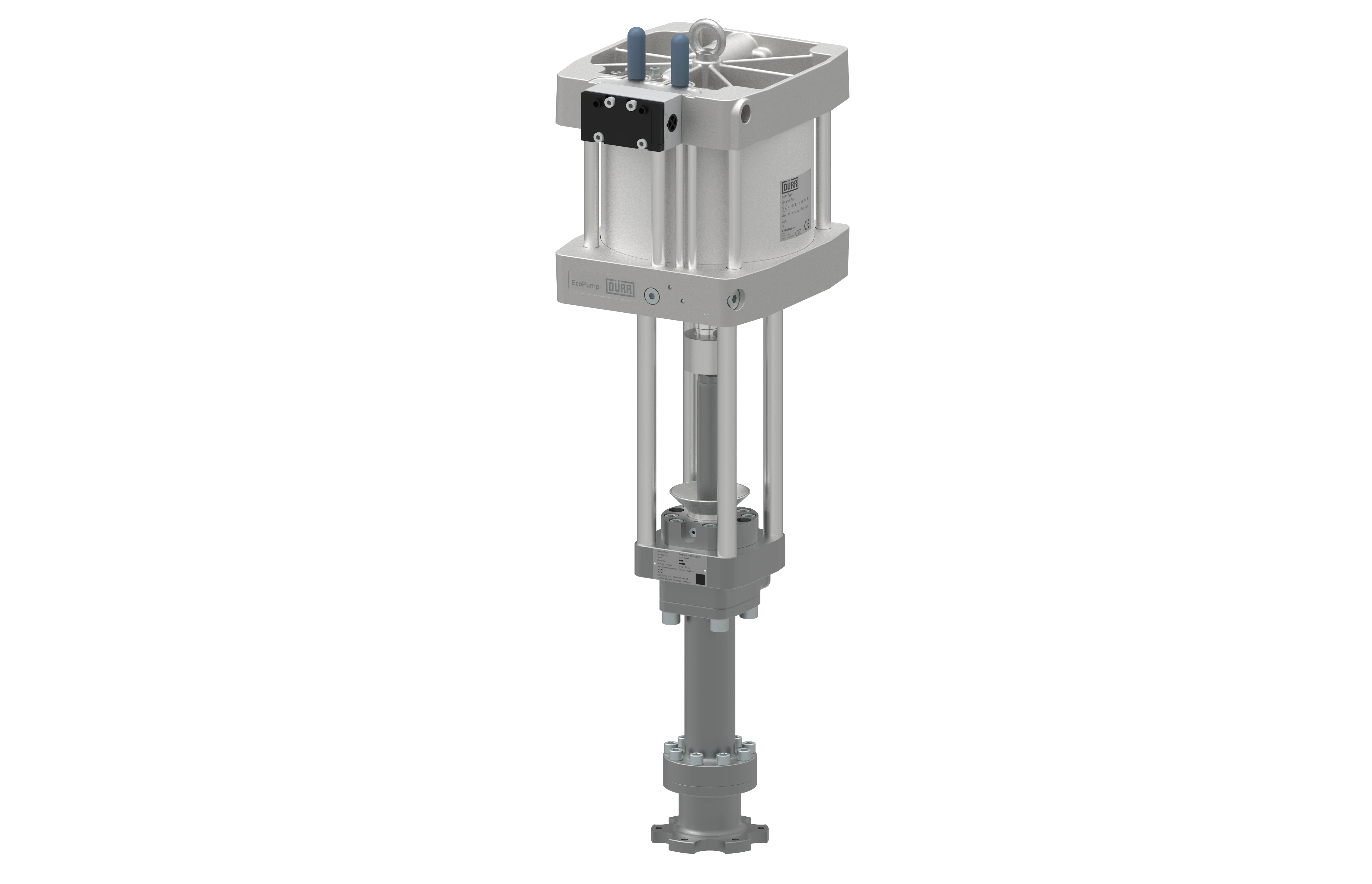

The EcoPump VP is a pneumatically driven vertical piston pump for medium and high pressure applications. Proven design and long term durability make these pumps the perfect choice for small and middle applications of paint, mastics and adhesives to furniture, steel structures or walls, car bodies and other objects. The EcoPump VP is suitable for airless or air-assisted application and is available in numerous configurations with various air inlet modules, pressure relief valves, trolleys and adjacent devices.

The EcoPump VPS is an air operated chop-check pump for medium to high viscosity fluids as glues, oils or wax. Its modular design allows an easy maintenance and with it, optimized fluid part the material will be pumped considerately. The proven design and a long term durability make these pumps the perfect choice in the high viscosity application.

A wide choice of manufacturing materials for the pump housing makes the EcoPump AD the best solution for different kinds of fluid handling such as abrasive and particle containing fluids. The typical field of application of the EcoPump AD is to handle oil, water, waste liquids with and without solid particle debris, water and solvent borne paints, varnishes, enamels and lacquers. The EcoPump AD pump will operate in circulation or direct fluid delivery mode. The simple design of EcoPump AD allows easy maintenance and service.

The pump packages are fully assemblied portable modules, which are ready to use. The modular design ensures a use in multiple industries including wood finishing and exterior painting. Equipment for high-pressure coating based on EcoPump VP pumps are available as well as low pressure coating devices which use a line of diaphragm pumps. Variability is ensured by wide configuration options where the selection is made between different assembly modules like carriage, suction type or optional accessory to extend user’s comfort.

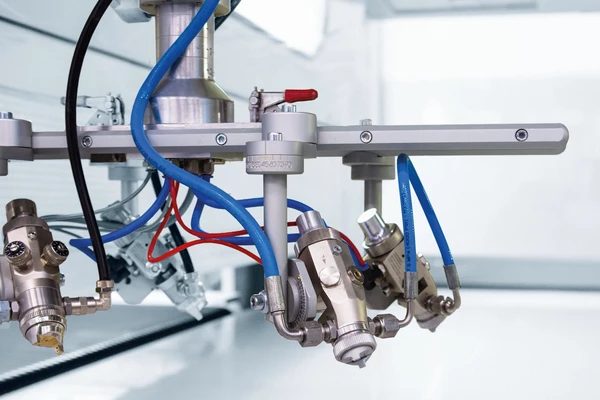

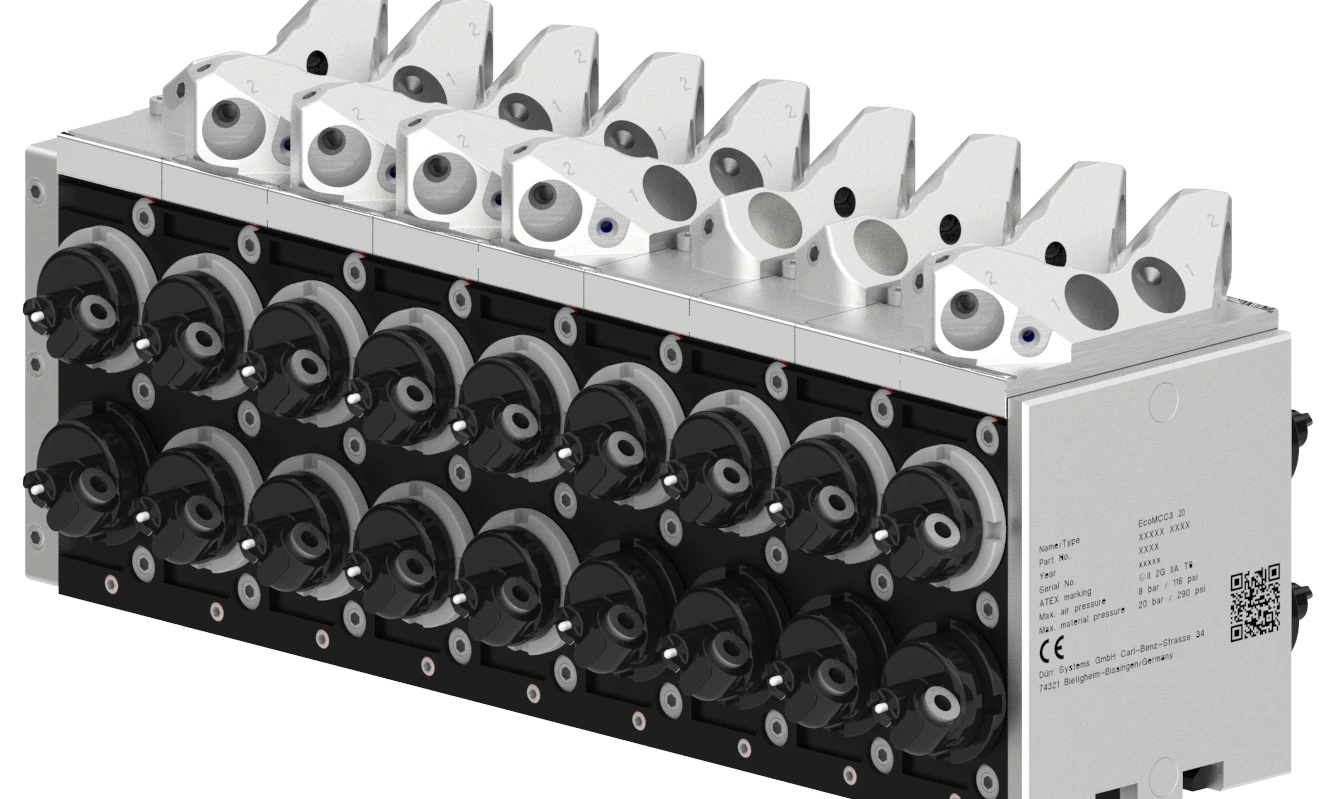

The EcoMCC3 20 low-pressure color changer stands for fast color changes, low color change losses and easy maintenance. It is suitable for all water- and solvent-based 1K paints. Each color can be connected to the EcoMCC3 20 color changer in either direct or recirculating mode.

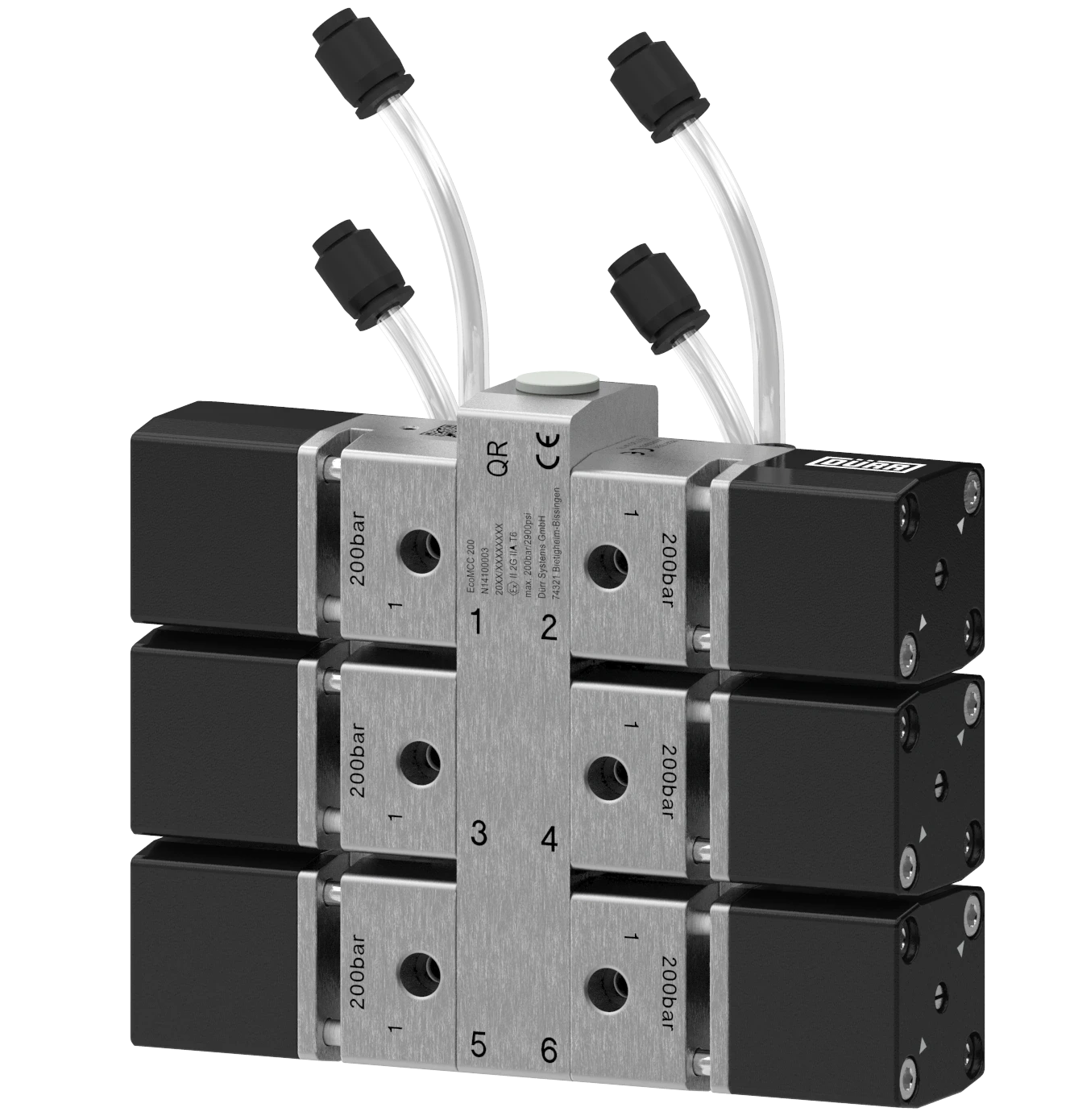

The EcoMCC 200 is a color changer designed specifically for high-pressure applications with water and solvent-based paints. It can also be used for 2K paints or as a dosing valve. Reduced dead spaces allow for quick flushing of the color changer. The double seal allows for the detection of valve defects before affecting other components.

The EcoValve7 20 color changer family is used for demanding 2K paints in the low-pressure range. Unlike traditional paint valves, the needle is sealed not by a packing but by a membrane, which eliminates gradual leaks. Hose bursts are also prevented, as the valve automatically opens in case of overpressure. It is known for very long service life and easy-to-clean surfaces. The integrated needle seat allows for quick and simple maintenance.