Versatile and sophisticated – Our paint supply systems

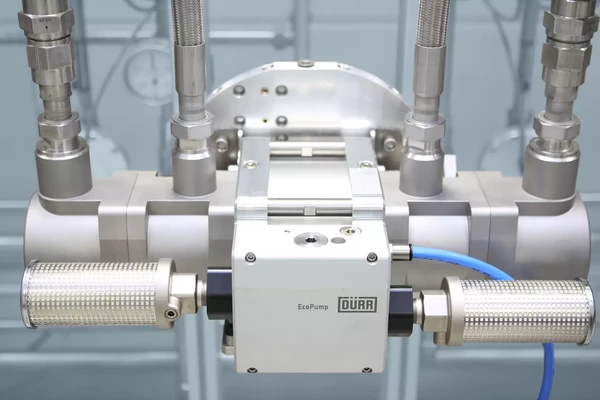

Dürr develops all the products required for paint circulation and supply itself, including pumps and color changers, pressure controllers, valves, pressure tanks, agitators, filters, pressure gauges, and hoses.

Our fluid handling equipment

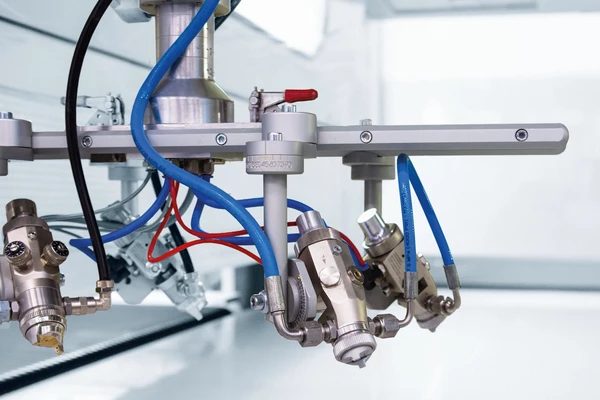

EcoFlow HPF – High pressure regulator flow

The EcoFlow HPF is a high pressure flow regulator designed to maintain downstream pressure in application supply systems. By controlling the media pressure to the required working pressure, connected applicators are protected against pressure surge and pulsation from the material supply, while maintaining the required pressure and flow characteristics for the application process. Typically handled materials are high viscose media such as mastics, sealers, pastes, adhesives or glues.

EcoFlow HPR – High pressure Regulator Return

The EcoFlow HPR is a high pressure return regulator designed to maintain consistent back pressure in application supply systems. By controlling the fluid pressure to the required working pressure, applicators are protected against pressure surge and pulsation from the material supply, while maintaining the required flow characteristics for the application process. The EcoFlow HPR is easy to maintain with a 100% tight sealing function and compact dimensions. Typically handled materials are highly viscose media such as mastics, sealers, pastes, adhesives or glues.

EcoFlow LPF – Low pressure fluid regulators

The EcoFlow LPF is a low pressure flow regulator designed to maintain downstream pressure in paint supply systems. By controlling the fluid pressure to the required working pressure, applicator equipment is protected against pressure surge and pulsation from the material supply, while maintaining the required flow characteristics for the application process. Typically handled materials are water and solvent borne paints, varnishes, enamels and lacquers.

EcoFlow LPR – Return low pressure fluid regulators

The EcoFlow LPR is a low pressure return regulator that has been designed to maintain consistent back pressure in application supply systems. By controlling the fluid pressure to the required working pressure, applicators are protected against pressure surge and pulsation from the material supply, whilst perfect flow characteristics for the application process are ensured. EcoFlow LPR is easy to maintain with a 100% tight sealing function and compact dimensions. Typically handled materials are water and solvent-borne paints, varnishes, enamels and lacquers.

The Dürr pressure pot product group is available with or without pneumatic agitators. Pressure pots are suitable for all fluids and solvents supplying manual or automatic spray guns or other equipment.

Great advantage of pressure pots is smooth material delivery without pulsations. There is a line of pressure pots with different volumes available.

Filters HP – High pressure material filters

High pressure filters can be used for the filtration of paint or any other kind of fluid. Several different filter sizes are available. The filter design allows a tool free filter maintenance. Up to four devices can be connected (three on the sides, one on the bottom). Due to its robust design the filter can be used in low- and high pressure applications with a maximum fluid pressure of up to 500 bar (7,250psi). Additionally the filter helps to reduce the fluids‘ pressure pulsation.

Filters LP – Low pressure material filters

Low pressure filters can be used for the filtration of paint or any other kind of fluid. There are several filter types available. The low pressure filters are available with either a “bag“ or cartridge element.

Dürr has a broad range of gauges for paint material pressure measurement. Whichever you choose you can rely on high quality reability of these parts.

As an enhancement to the EcoPump HPE, the Pressure Relief Valve prevents possible damages caused by unpredictable excess pressure. It is simply connected directly to the outlet of the pump. Protection against pressure peaks and improper use is guaranteed by closing the ball valves. By using the optionally available sensor in the relevant port, the pressure relief valve is the perfect interface to allow full closed-loop functionality. Typical fluids include water and solvent borne paints, varnishes, enamels and lacquers.

Agitator A MAN - Manual air operated agitators

Dürr has developed a group of pneumatic Agitators for use in the preparation of paint before application or to prevent settling of the paint during spraying. Various shaft lengths are available. Optional stand is available to allow mixing without assistance of the operator. The pneumatic drive allows the safe use in a paint shop environment.

- Suitable for paint shops

- Manual speed regulation

- Optional stand

- Stainless steel shaft and propeller

- Wide range of shaft lengths available

- Easy operation & maintenance

Agitator A FIX - Fix mounted air operated agitators

Good preparation is essential for high quality application of the material (paint, glue, penetration etc.). For large containers agitation, Dürr has developed a line of fixed mounted agitators. They are available for 60 or 200 liter (15 or 60 gallon) tanks. The agitators are air operated and usually fixed to the lid of the container. There are multiple propellers available selected by the material used.

- Propeller made of stainless steel

- Usable in explosive hazardous environment

- Multiple propeller sizes and types

- Air inlet regulator for speed control

Every application requires some sort of media connection. There are hoses which can be used for pneumatic motor air supply and atomization air for air spray guns. On the other hand there are hoses for fluid supply (paint, glue etc.) from pressure pots to automatic air spray guns. High pressure hoses are used for delivery of high viscose materials from high pressure pumps. There is a wide range of Dürr hoses that fit into any possible application. Easy configuration on our webshop helps you to select the right hose for your needs.