Worldwide, more than 10,000 Dürr air pollution control systems protect the environment from hazardous substances and reduce the carbon footprint of a wide range of industries. This enables companies to meet both statutory requirements and individual company goals aimed at making industrial processes more environmentally friendly. Dürr’s air pollution control products offer solutions for industrial processes that produce fine particulates, volatile organic compounds and hazardous atmospheric pollutants.

“Dürr is the world’s leading provider of industrial air pollution control. With our extensive array of products and associated product brands, we stand out as a global market leader,” emphasizes Dr. Daniel Schmitt, President and CEO of the Clean Technology Systems Division at Dürr Systems AG.

Modifying the brand architecture

Until now, Dürr’s exhaust gas and air pollution control products have been marketed under the Ecopure® brand. With the acquisition of Megtec, its products have now been added to the array. The new product branding strategy is, therefore, the next logical step in providing a clear structure for the comprehensive portfolio. All of the Dürr Group’s air pollution control products are bundled into product families according to their technology. Each also has the suffix “.X” to emphasize Dürr’s commitment to excellence.

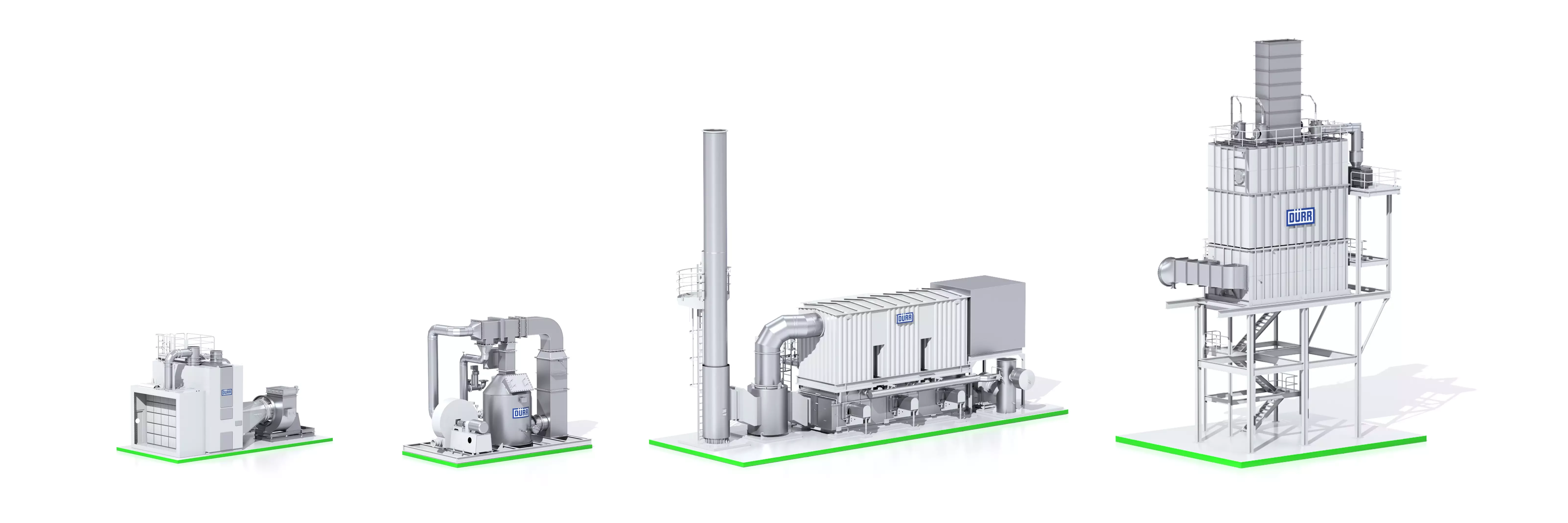

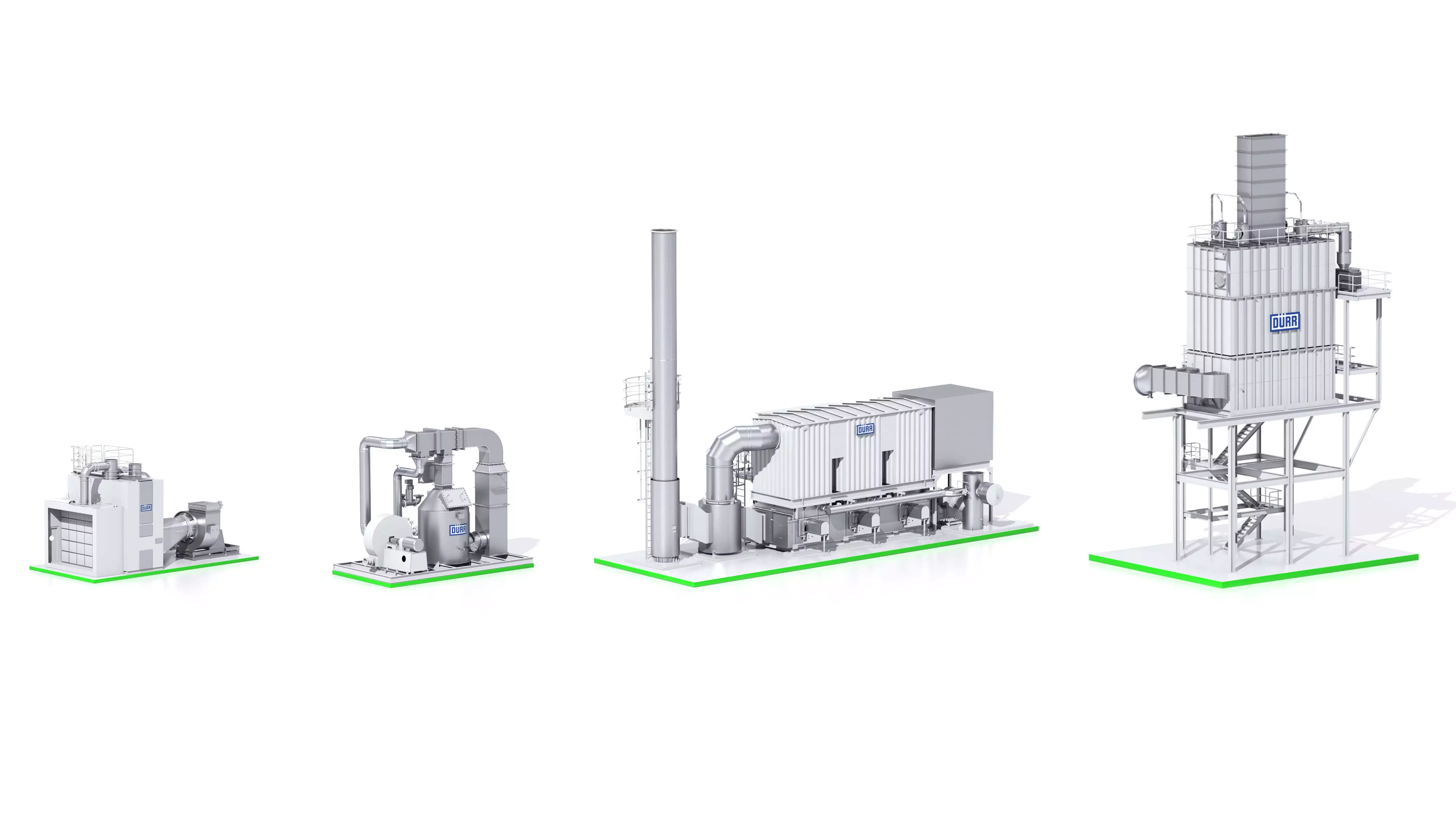

Organizing the air pollution control portfolio into five groups

Every production process has its own requirements for air pollution control and requires the right technology for the job. Dürr divided the different methods, products, and services into five groups: Oxi.X for oxidation technologies, Cat.X for catalytic air pollution control systems, Sorpt.X for sorptive methods, Part.X for particulate control technologies, and Service.X for global service activities over the entire life cycle of the air pollution control systems.

“Our products’ new brand architecture increases the visibility of our Dürr and Dürr Megtec portfolios for customers in need of environment technology,” says Dr. Daniel Schmitt, explaining the significance of the new naming concept. “With our comprehensive and harmonized range of products and services, we are well-equipped to make a significant contribution to improving sustainable industrial production in partnership with our customers.”

Overview of industrial air pollution control technologies

- Oxidation technologies use thermal processes to remove harmful substances from the exhaust air. This method is suitable for a wide range of industries and types of hazardous substances. Dürr offers more than ten different products in the area of thermal oxidation.

- In catalytic air pollution control systems, hazardous substances are removed using a catalytic converter. This is because catalytic converters need much less energy to trigger a chemical reaction. Dürr uses catalytic converters for both oxidation and reduction processes.

- Sorptive methods can be based on absorption or adsorption. With adsorption, hazardous substances undergo adsorptive concentration. This preparatory step permits efficient purification of the concentrated exhaust air. Dürr also offers systems for solvent recovery based on adsorption. With absorption, hazardous substances are removed from the exhaust air using, for example, scrubber technologies.

- Particulate control technologies use the physical properties of substances to separate hazardous substances from the exhaust air. Dürr products that separate fine particulates, acid mists, and aerosols from industrial gases include wet and dry electrostatic separators, as well as venturi scrubbers.