Established in 1964, Dürr Brazil is an important partner in various industrial sectors in South America. With approximately 300 employees, its role consists of developing complete systems for the automotive industry as well as providing modernization to existing lines.

Safety, ergonomics and efficiency

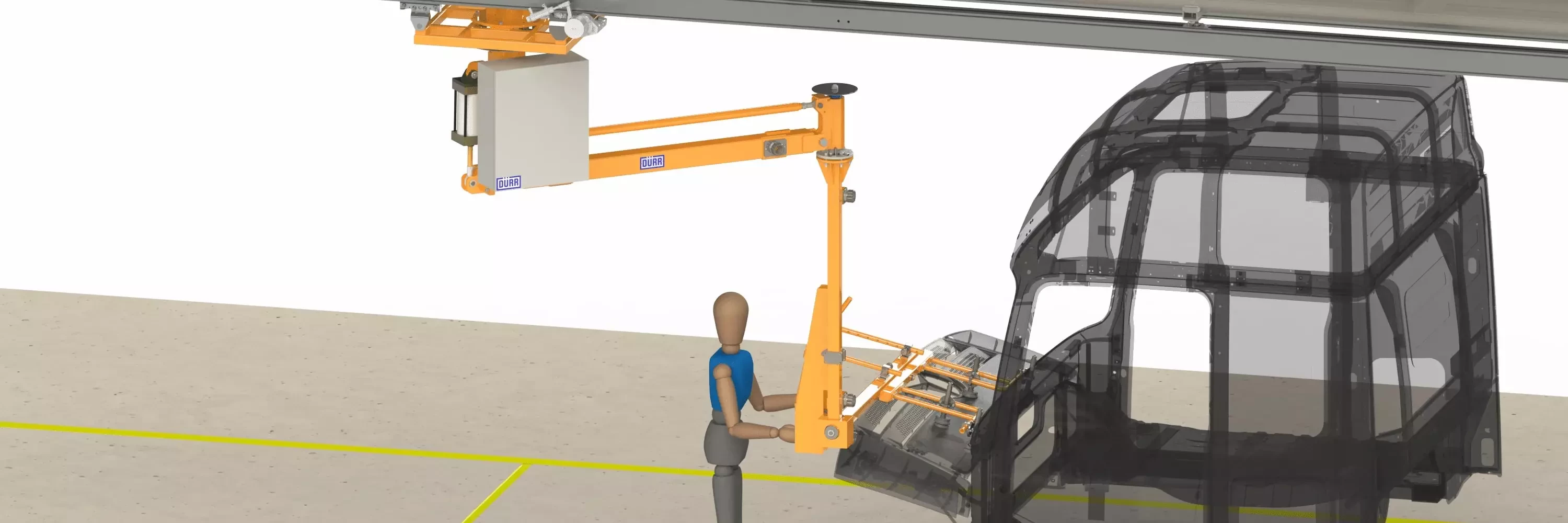

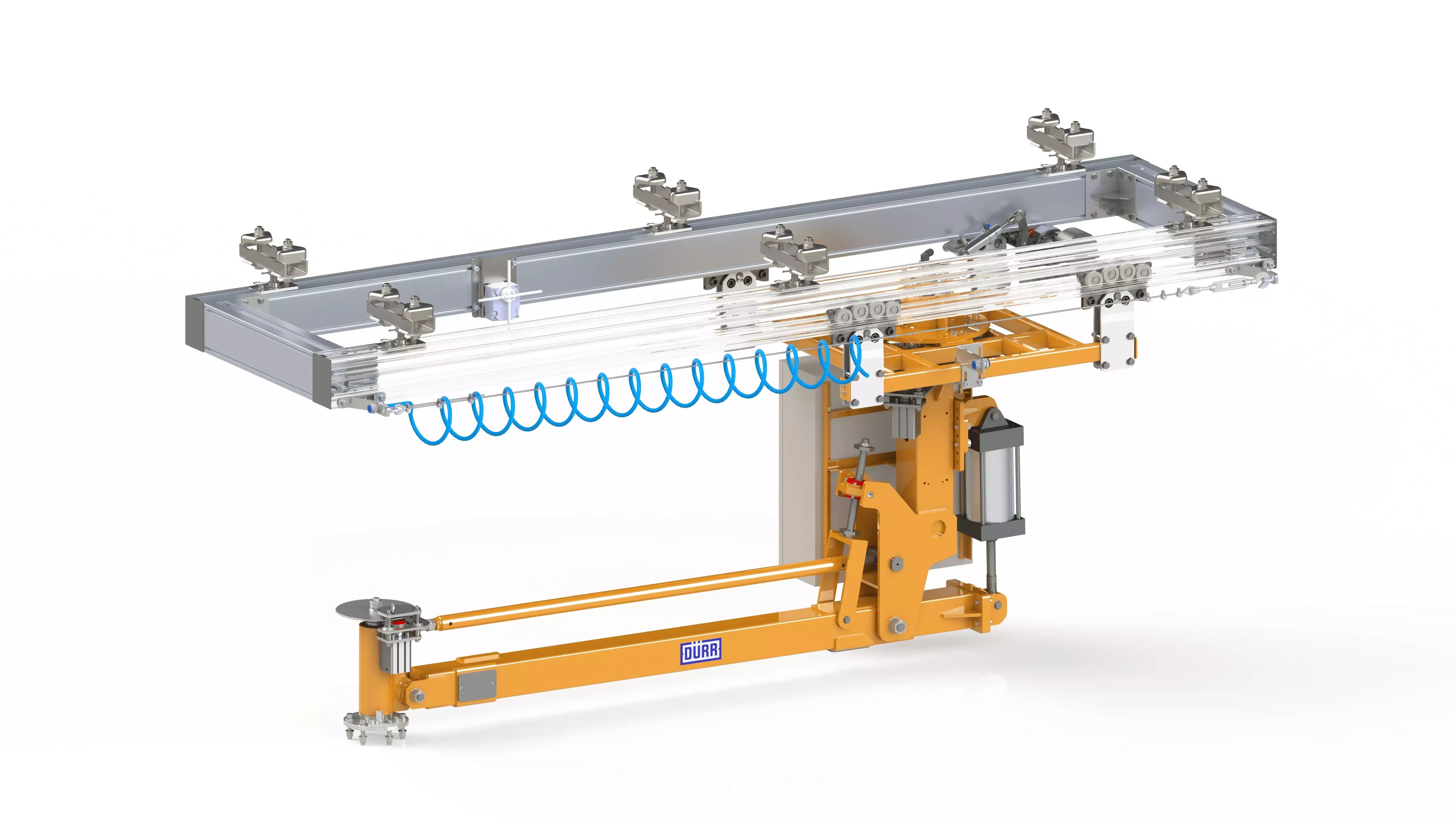

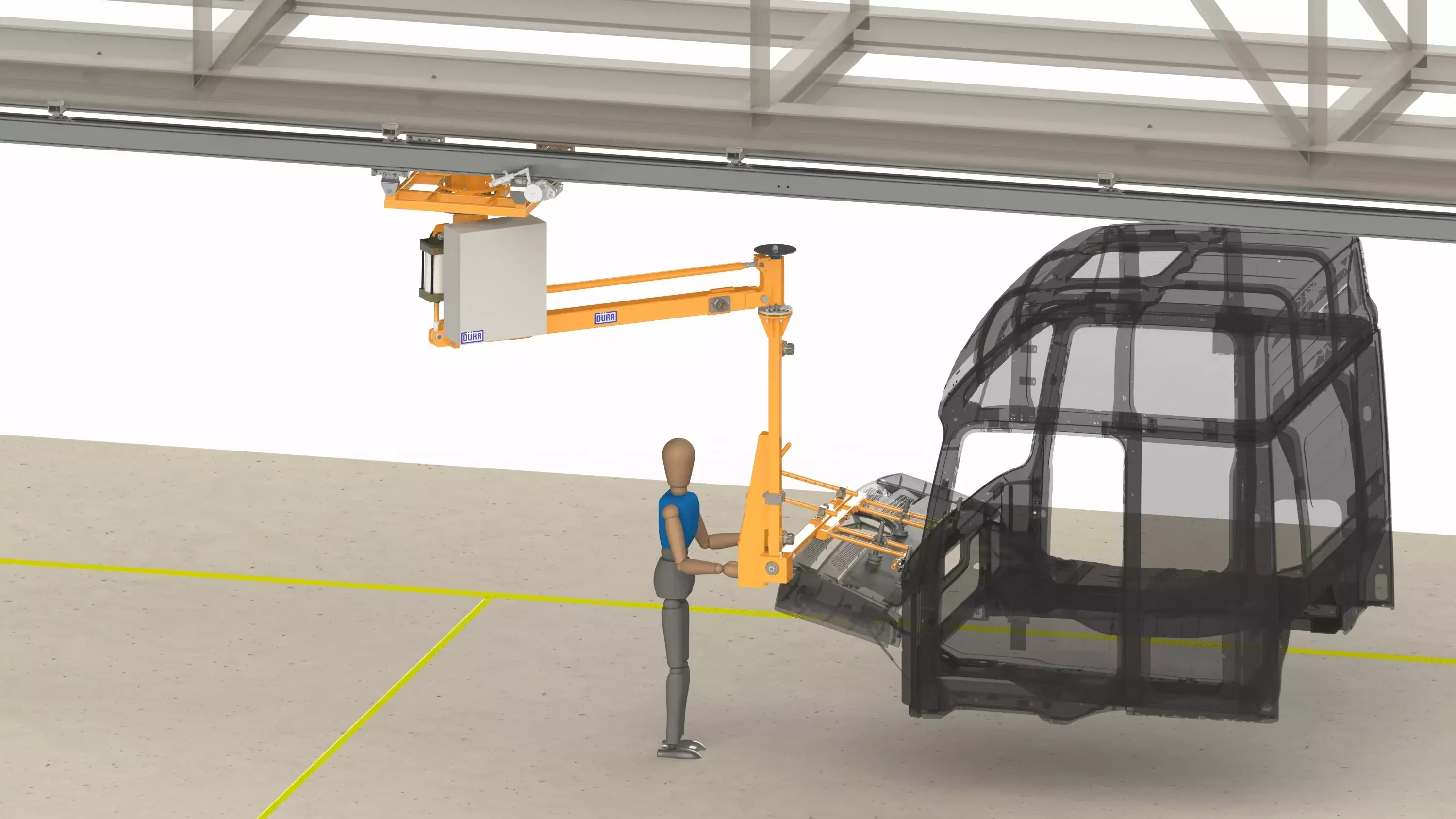

The new manipulating equipment was developed based on Dürr Brazil’s extensive know-how in automotive assembly lines. Manipulators are used when a product or component to be moved is heavy, has low stability or when it needs to be placed in areas with limited access - avoiding any safety risks during handling. With Dürr’s manipulators, a safe and ergonomic handling of products in all directions is assured.

Advantages of manipulators

Agility, ergonomics and safety for operators, parts and vehicles are some of the benefits using Dürr’s manipulators.

With a specialized team, responsible for the entire development process, Dürr presents the improvement of process efficiency at the lowest operating and maintenance costs.

Satisfied customers

Individual planning and simulations in advance eliminate possible process failures. In addition, in order to avoid potential failures, several internal tests are conducted before delivery and installation at the customer’s site. The application of Dürr’s manipulators is very wide and it’s possible to develop individual handling solutions for practically all components of an assembly line, such as doors, windshields, axles, instrument panels, wheels or other.

“Safety, ergonomic and efficiency are very important in assembly lines. With our manipulators we make the assembly process easier in production lines and contribute to a safer working environment”, says Stephan Roisin, MPS director in Sao Paulo.

Final assembly at Dürr

For the final assembly business, Dürr has set up a global strategy: NEXT.assembly. The strategy integrates all of Dürr’s technology and consulting spectrum in a one-stop-shop solution aimed at enabling manufacturers to assemble vehicles as efficiently as possible. The building blocks for this are conveyor, gluing, marriage, filling, and testing technology as well as digital solutions for intelligent control of overall production. Dürr offers the portfolio as a modular system of individual components or as a complete solution.