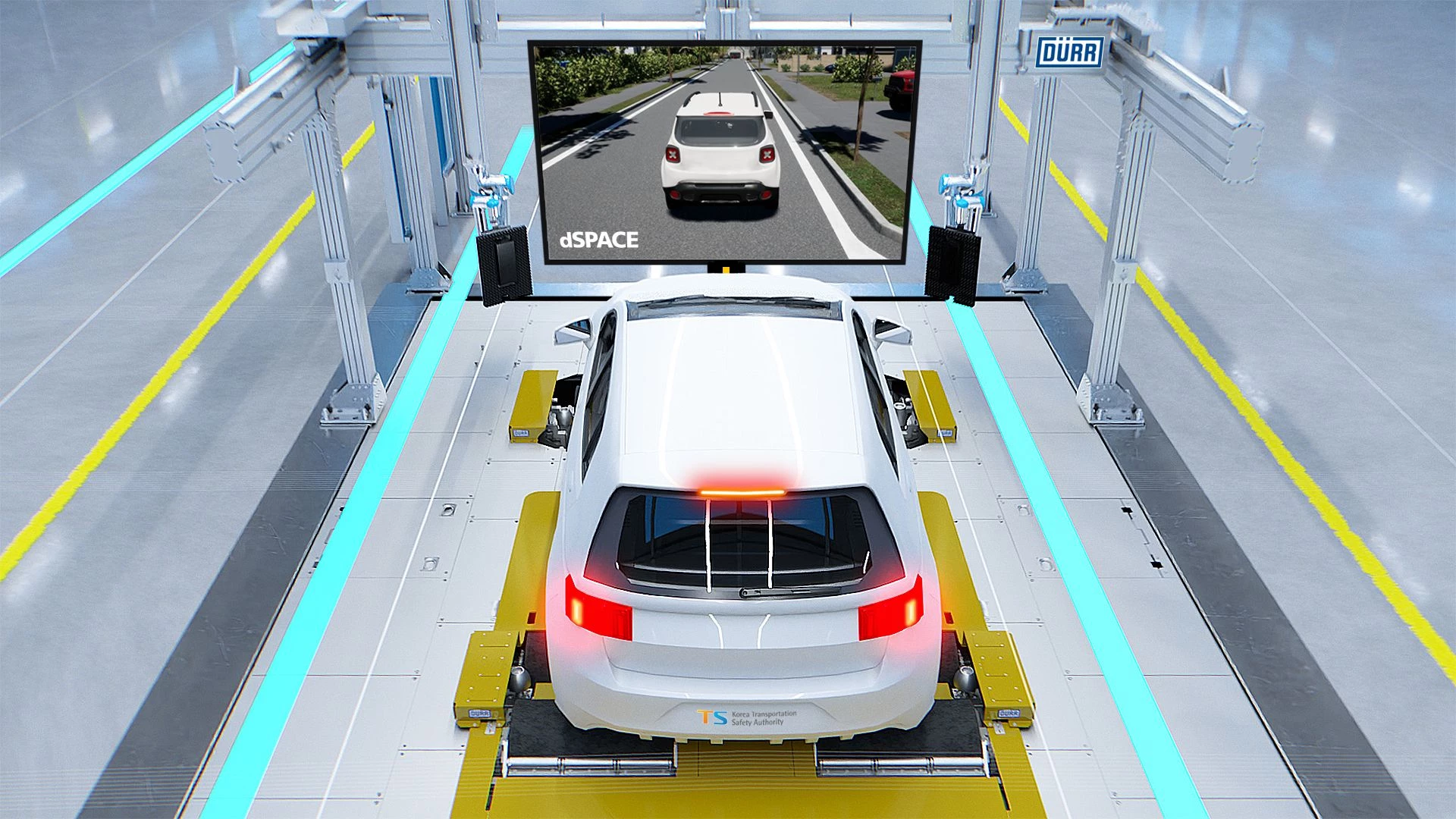

Advanced driver assistance systems (ADAS) help drivers by providing a variety of functions such as lane departure warning, adaptive cruise control, and emergency braking assist. They help reduce the risk of accidents and collisions, thereby increasing road safety. The question of how to ensure the reliability of ADAS in the long term with the help of test methods is the subject of lively discussion among vehicle monitoring authorities. At the conference of the International Motor Vehicle Inspection Committee (CITA) – the global umbrella organization of motor vehicle inspection organizations and their suppliers – the Korean authority KOTSA presented its successes in ADAS functional testing using its first vehicle-in-the-loop (VIL) test setup. The VIL setup consists of Dürr's patented x-road curve chassis dynamometer, on which the test vehicle can be accelerated, braked, and steered, as well as the DARTS radar target simulator, ASM simulation software, and the AURELION visualization tool from dSPACE. This enables KOTSA to create a virtual environment, especially for the camera and radar sensors installed in the test vehicle, to represent a wide variety of inspection scenarios. These scenarios include critical situations such as vehicles ahead braking suddenly or cutting in directly in front of your own vehicle. To pass the test, the test vehicle must respond to new situations in the VIL simulation in real time and, if necessary, trigger the emergency brake assistant, for example.

In a new project which will run until 2026, the simulation and validation experts at dSPACE and the test engineering specialists at Dürr are now taking the next step with KOTSA. Together, the existing initial VIL setup is to be further developed for widespread use in test benches throughout South Korea. In parallel, KOTSA plans to initiate the corresponding adjustments to the Korean inspection regulations. Internationally, the South Korean road safety authority is thus one of the pioneers in the field of ADAS function testing, which is not yet a mandatory part of the main inspections in any country in the world.

"With this procedure, test organizations and technical services worldwide have the possibility to generate reproducible and, above all, reliable test results. The test bench is a scalable starting point for testing future highly automated vehicles," says Ahmet Karaduman, Consultant and Project Manager of ADAS vehicle-in-the-loop projects at dSPACE.

Kai Künne, Product Manager for Autonomous Vehicle Testing at Dürr subsidiary Dürr Assembly Products, adds: "Thanks to the cooperation with dSPACE, we are increasing safety for all users of automated driving functions with our innovative test bench concept. At the same time, we want to boost confidence in the autonomous vehicles of the future."

For the first time, manufacturers, inspection service providers, and inspection authorities can use this approach to perform automatic, reproducible, and traceable tests under controlled conditions at a test site. This alternative to the currently very costly and difficult-to-repeat vehicle tests on closed-off test tracks enables efficient recurring main inspections for driver assistance systems.