The battery serves as the primary power source for electric vehicles, essentially acting as their heart. Due to the challenging conditions on roads, vehicle requirements in terms of puncture resistance, vibration resistance, waterproofing, moisture-proofing, air isolation, and heat dissipation are necessary, especially for the battery pack. A precise gluing process is one of the core factors in achieving a stable, efficient, and durable operation of an electric drive system. Only when each battery unit is securely connected and the thermal management of the pack is built up properly can the performance, safety and longevity of the entire battery system be ensured. This largely determines the success of the electric vehicle.

Dürr's dispense technology is the cornerstone in high-quality battery manufacturing. The modular system adapts to various adhesive material viscosities and mix ratios, ensuring precise and even material application. Whether sealing, structural bonding, TIM (Gapfiller), Dürr's battery dispense application technology spans the entire assembly process, from cells to modules and battery packs. Dürr is proficient in every gluing and sealing process, ensuring safety and quality throughout the production process to achieve battery system stability and durability. Thereby several modules play an important role in the gluing application system.

Material supply of viscous glues

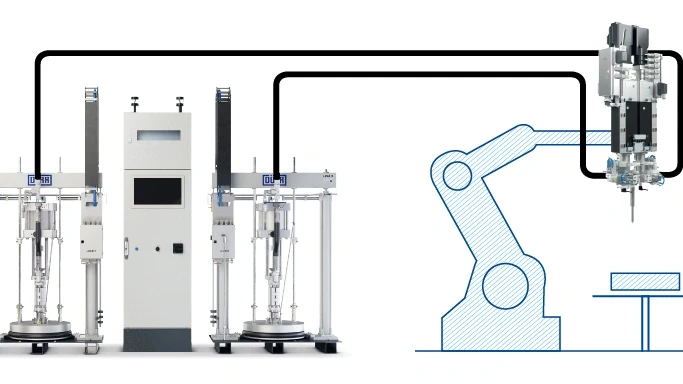

The EcoRAM is a drum press compatible with all of Dürr’s gluing machines, available in unheated and heated temperature-controlled variants. These variations ensure the effective pumping and dispensing of viscous glues. The system can be configured as either a single- or double-drum pumping station.

Control system of pumps and applicators

The EcoHVMP consists of a modular, extendable control cabinet equipped with standard components to control pumps and applicators. The compact control (Safety PLC) operates without complex and costly cable guides. Plug connectors facilitate rapid electrical and pneumatic installation. Dürr’s EcoHVC software includes numerous analytical tools and is Industry 4.0 compatible.

Accurate metering systems

The EcoShot Meter, an electric piston dosing unit, accurately doses highviscosity materials regardless of material supply variations. It is suitable for applications demanding exceptional dynamism and process precision. Fully integrated into the EcoHVC control system, this double dosing unit allows for continuous material application or a 2K application.

Versatile applicators

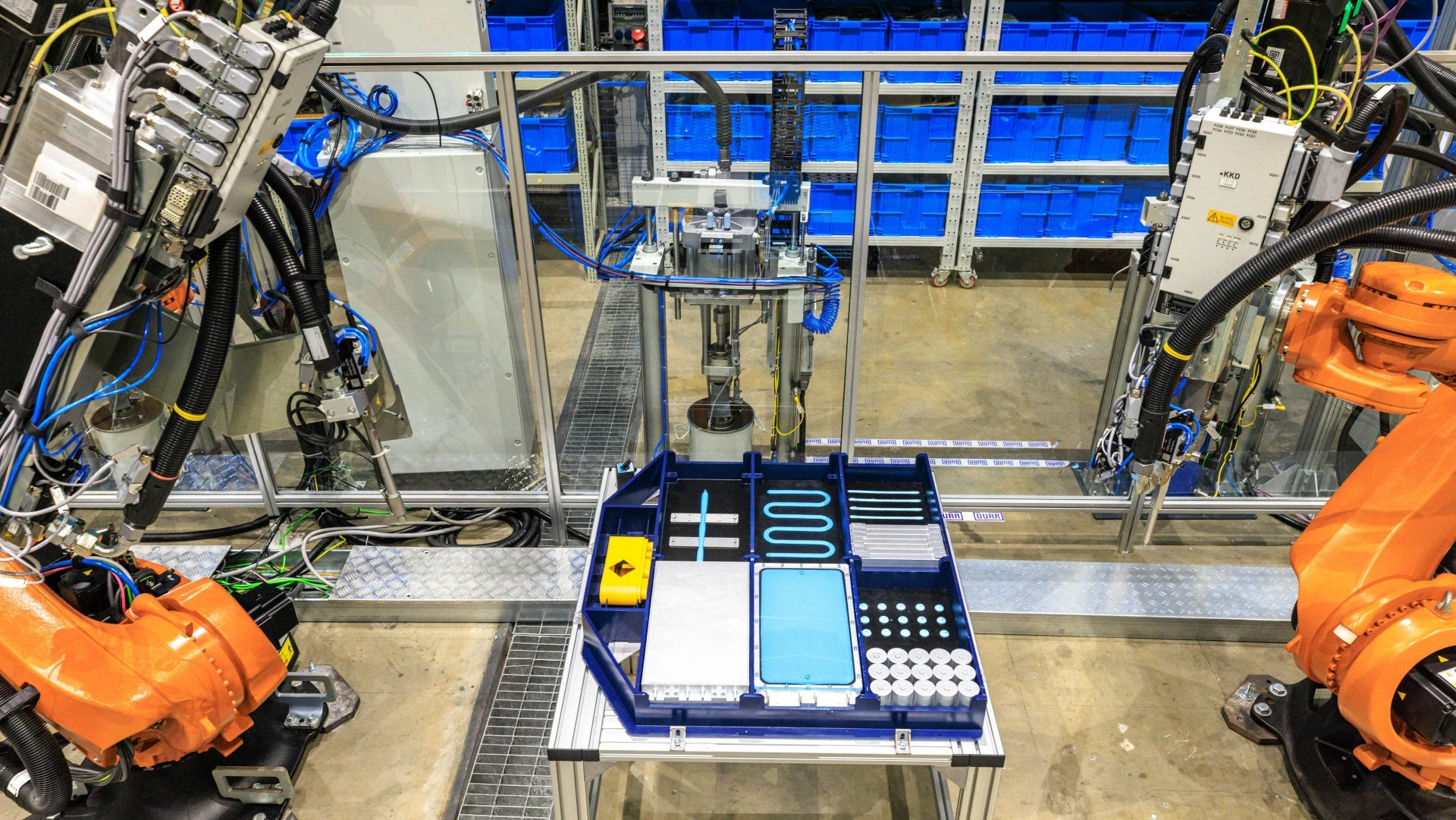

EcoGun applicators offer versatility by accommodating various nozzles depending on the application task. They handle highly viscous adhesives, creating different bead cross-sections while ensuring optimal quality at each end of the bead. These applicators are used for robot application, on the bonding tower, and work with both 1K and 2K materials.

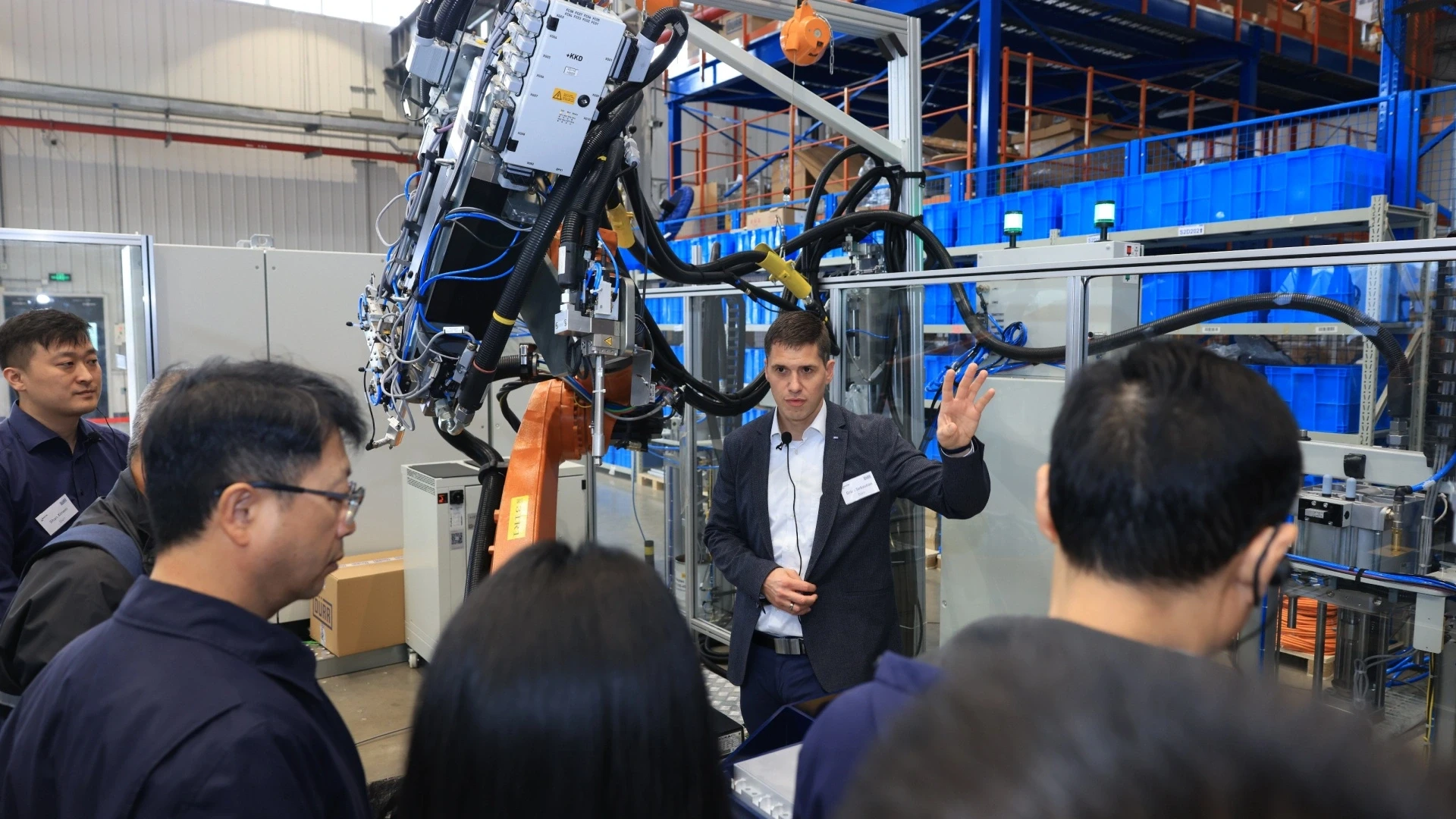

Battery gluing is one component of Dürr’s comprehensive services within battery manufacturing. Andre Hurst, Application Technology vice president from Dürr China said: “We have diversified battery production solutions, covering cell manufacturing, module assembly, battery pack assembly, and battery integration, and are committed to achieving safe and high-quality battery production."

Mo Liu, Mobility business director from Bostik, a partner of this event, highlighted, "Dürr’s partnership with Bostik enables flexibility and adaptability in applying various viscosities and mixing ratios of Thermal Conductive Adhesives for more effective thermal management." As a leading global adhesive specialist, Bostik is introducing its new Thermal Conductive Adhesives to address the thermal management challenge in the latest Cell-to-Pack battery design for e-mobility solutions.