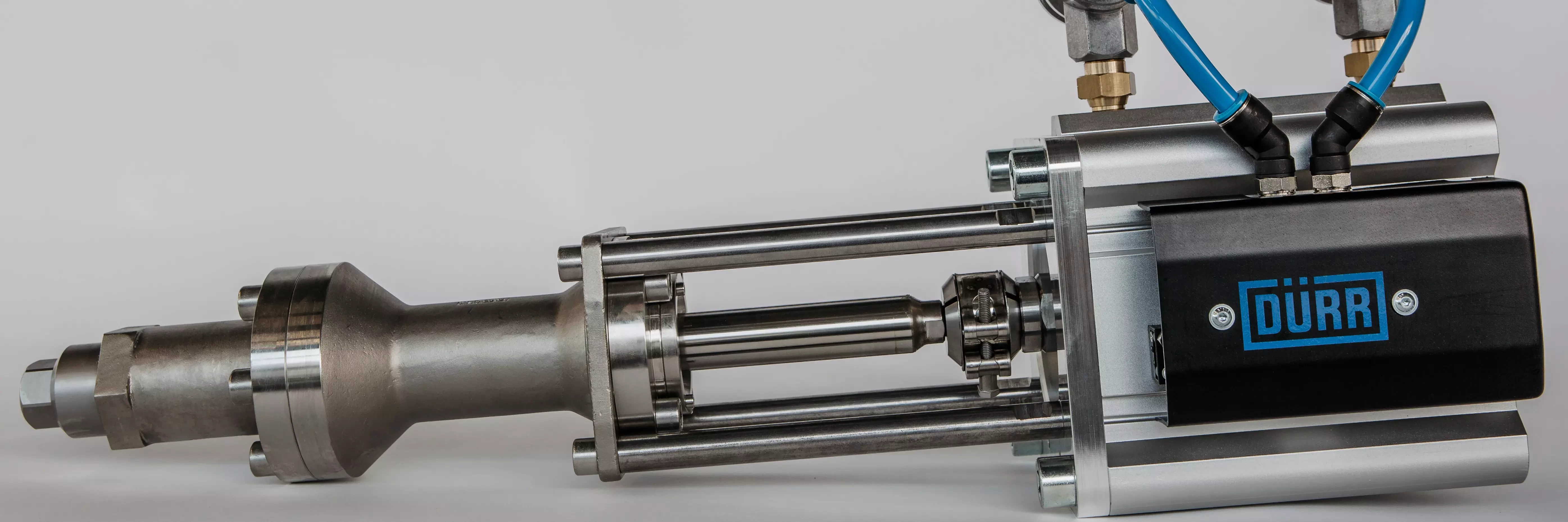

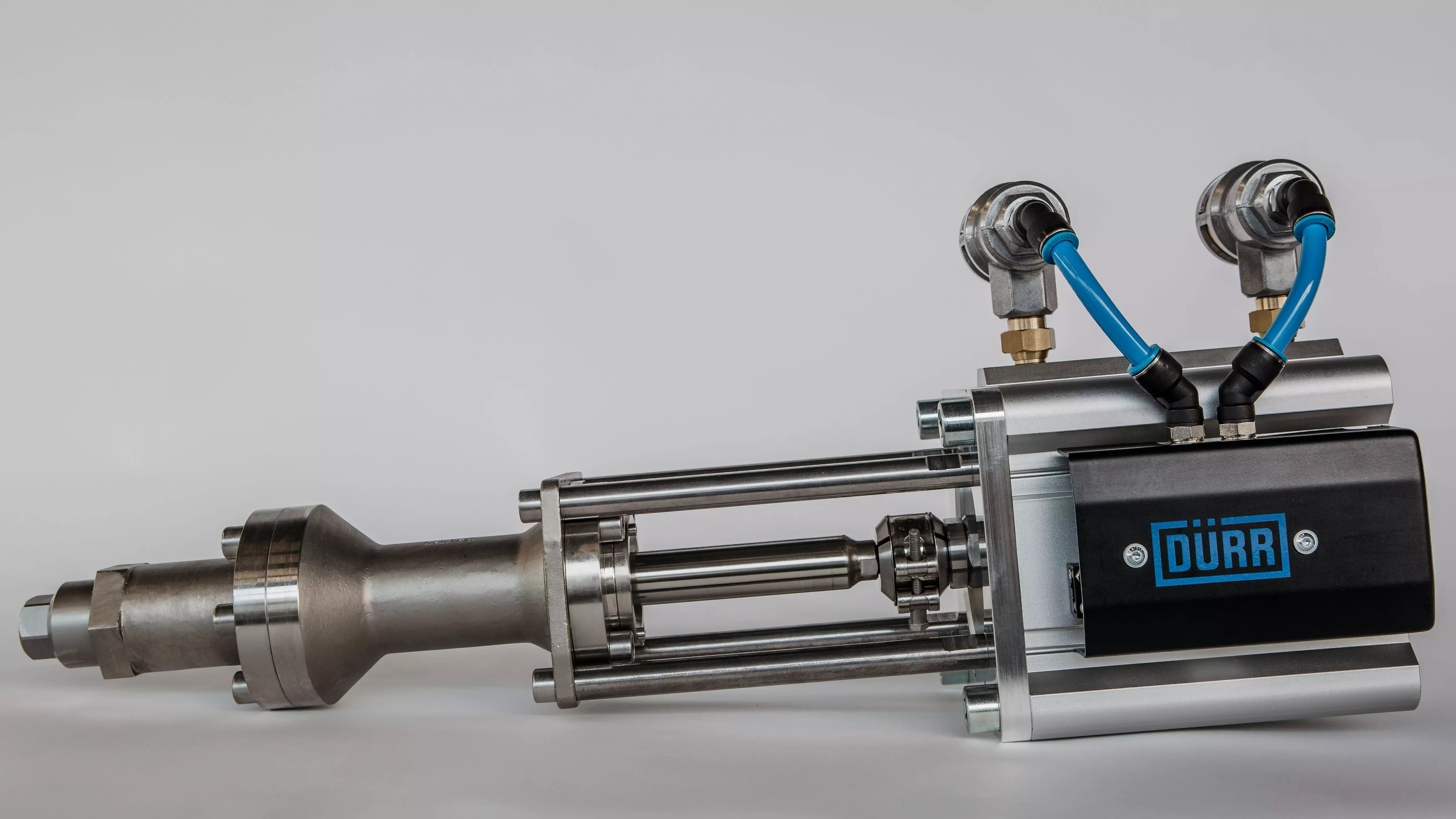

The new pump only needs one seal for the majority of applications, which is also much quicker and easier to change than on the predecessor model. The fluid parts can be disconnected from the air motor with conventional tools via a quick coupling. The new air motor can be operated without any oil. This significantly reduces the maintenance required, including in comparison with the competition. A further benefit is that the contactless changeover valves used to regulate the air motor changeover guarantee higher process reliability. Using quick-exhaust valves cuts changeover times, reduces pulsations, and increases performance.

With five different versions of the EcoPump2 VP covering a pressure range from 22 to 306 bar, the pump is suitable for applying paints, high-viscosity materials, and adhesives to furniture, steel constructions, and many more materials. It can also handle acidic hardeners commonly used in the 2K process in the North American market without any difficulty.

The first feedback from customers has been consistently positive. The pump is quieter, it pulsates less, and takes less time to clean than the predecessor model. Dürr will be presenting the new pump generation at its stand at this year’s PaintExpo in Karlsruhe, the world’s leading trade fair for industrial painting technology.