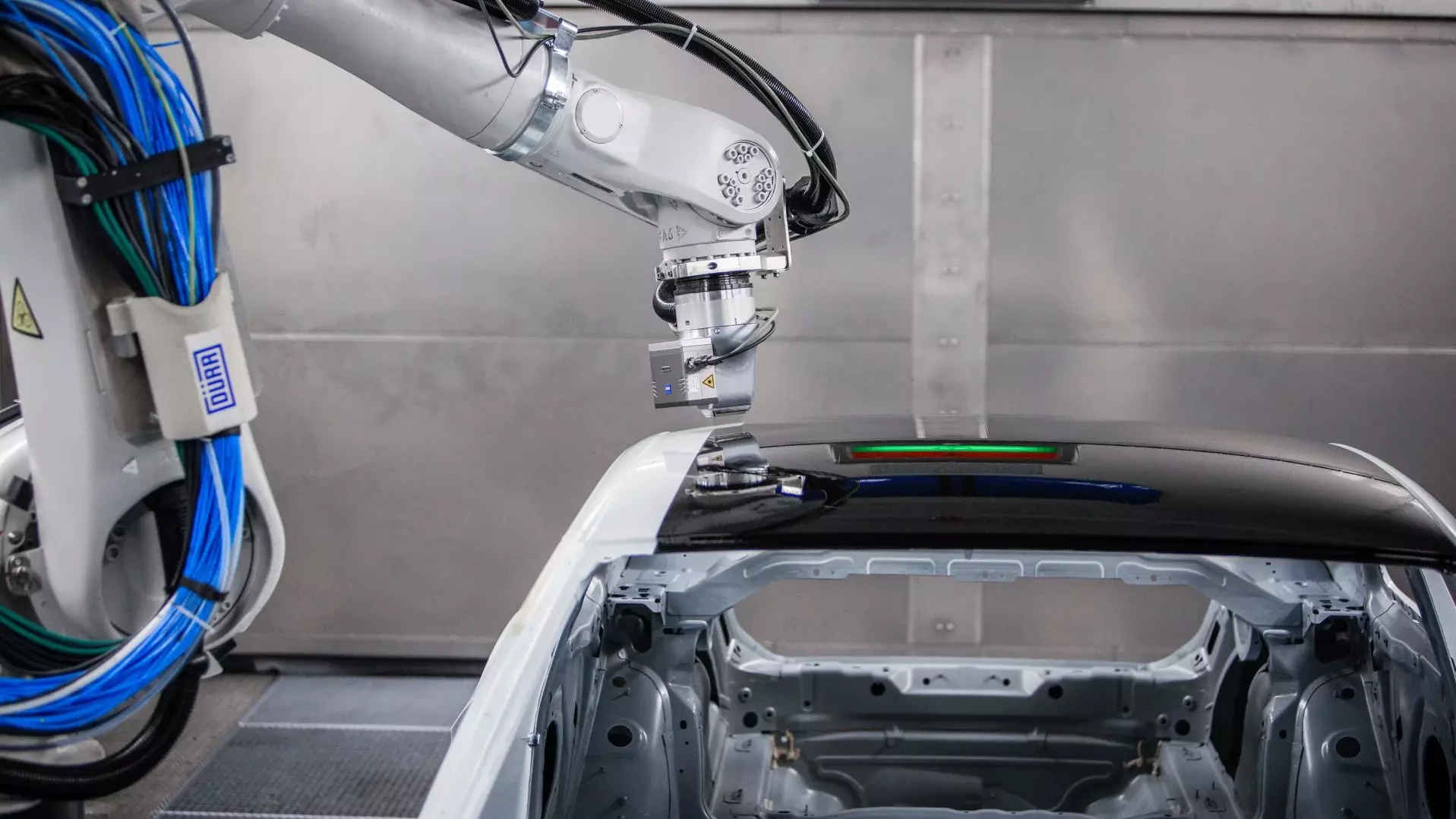

The EcoPaintJet combines know-how and high-tech components from the fields of paint application, robotics and software. Its core element is an innovative applicator mounted on a robot. Unlike a conventional rotating atomizer, it applies paint using an intricate nozzle plate. This has around 50 hardly visible holes with a diameter of approx. one tenth of a millimeter. The paint is applied through these holes in parallel jets from a distance of 30 millimeters – similar to an ink-jet printer. Prior to this, a measuring system measures the surface using a camera. Based on the measuring data, a software program calculates the paint paths along which the applicator hovers over the surface. The speed and tilt angle of the applicator are controlled such that the paint is applied evenly at all times. The contours of the surface are also taken into account, which is important when painting car roofs, for example.

The innovation makes product customization in automotive production significantly easier. If requested, it is possible, for instance, to apply decorative strips or contrasting colors to the car body roof fully automatically. “The EcoPaintJet enables us to support automakers in an important trend: An increasing number of car buyers want a customized vehicle. Our innovation offers completely new possibilities here – cost-efficient and fully integrated into series production”, says Dr. Lars Friedrich, member of the Dürr Systems AG Board of Management and CEO of the Application Technology division.

The EcoPaintJet does not generate any overspray since the paint never misses its target and only lands on the intended surfaces. This is why the rest of the car body no longer has to be masked using film when a second paint color is applied. The EcoPaintJet only needs 120 seconds to paint a car roof. Previously, the application and removal of the masking film alone took 50 minutes. In addition, around 15 square meters of masking film is now saved per car body. Further benefits include improved capacity utilization in paint shops and energy savings in the painting process of over 50% compared to a conventional two-tone process.

The EcoPaintJet is not only suitable for car bodies, but also for products where paint application has so far been highly labor-intensive. The range extends from wheels, furniture and two-wheeled vehicles through to cardboard packaging, garage doors and decorations for aircrafts and railway wagons.

The ‘Der Deutsche Innovationspreis’ award is one of the most renowned awards for innovations ‘made in Germany’ and is presented by the leading global professional services company Accenture, the energy supply company EnBW and the business magazine WirtschaftsWoche. It goes to enterprises that change business and markets with their innovative strength.