The award-winning overspray-free paint application combines the paint application system EcoPaintJet from Dürr and customized decorcoat paint developed by PPG. This makes it possible to apply paints on an automobile without the use of intricate masking to control where paint is applied. The EcoPaintJet technology is installed in the worldwide first serial production line for painting of two-tone cars without masking.

By enabling the paint to maintain crisp edges without the use of masking, the overspray-free paint application saves paint shops significant time. To meet the high requirements of car manufacturers, any automotive paint must meet the car manufacturer’s specifications for a wide range of properties such as color, adhesion, weathering, and appearance. With the new precision application process, a new set of requirements are demanded of coating formulations, which PPG's newly developed overspray-free paint meets.

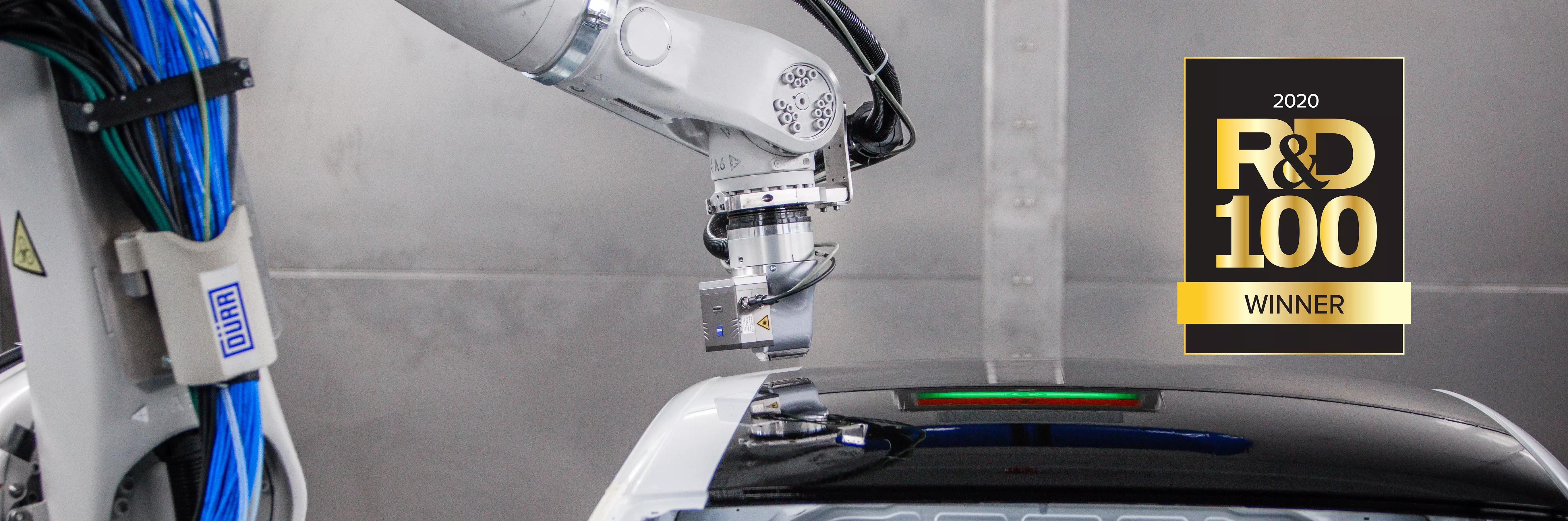

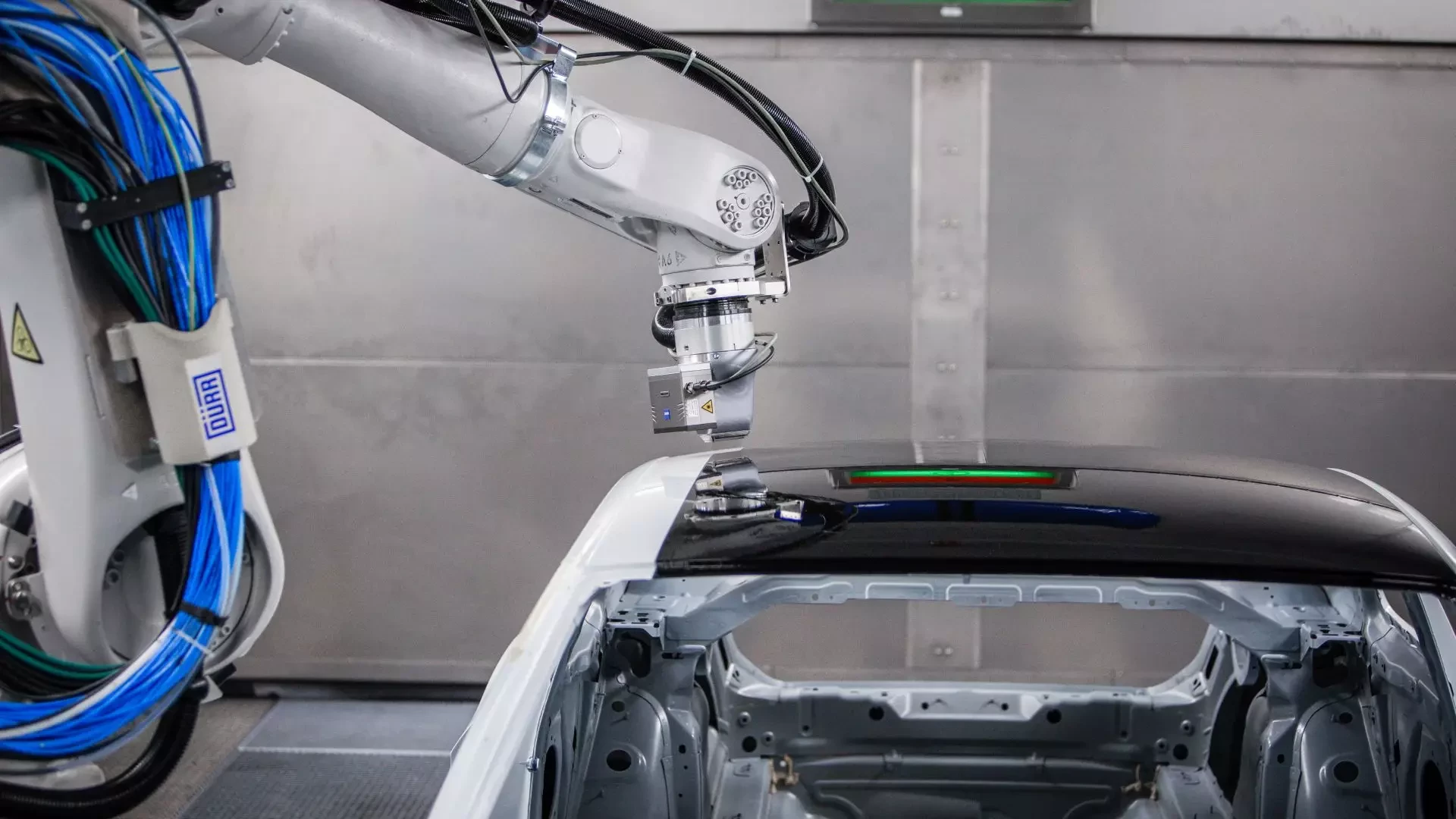

The EcoPaintJet incorporates know-how and high-tech components from the fields of paint application, robotics and software. Its core element is an innovative applicator mounted on a painting robot. Unlike a conventional rotating atomizer, it applies paint using an intricate nozzle plate. This has around 50 hardly visible holes with a diameter of approximately one tenth of a millimeter. The paint is applied through these holes in parallel jets. The 3D complexity of a car body requires a large painting distance, which can easily be achieved with EcoPaintJet. Because of the accurate paint application, each car body needs to be measured and the robot path calculated individually. This is accomplished by a robot-mounted laser triangulation sensor and Dürr´s powerful software.

The innovation makes product customization in automotive production significantly easier. For instance, if requested it is possible to apply decorative stripes or contrasting colors to the car body roof fully automatically. The EcoPaintJet does not generate any overspray since the paint never misses its target and only lands on the intended surfaces. This is why the remainder of the car body no longer needs to be masked using film when a second paint color is applied. The EcoPaintJet only needs tens of seconds to paint a car roof. Previously, the application and removal of masking film alone took nearly an hour. In addition, around 15 square meters of masking film is saved per car body. Further benefits include improved capacity utilization in paint shops and energy savings in the painting process of over 50% compared to a conventional two-tone process. Since there is no overspray, emissions of paint to the environment are reduced tremendously.

“Even during the currently difficult market environment, Dürr continues to invest in the future of paint application by developing disruptive hardware and software”, emphasizes Dr. Lars Friedrich, member of the Dürr Systems AG Board of Management and CEO of the Application Technology division. “The EcoPaintJet technology is a major step forward in automation and sustainability. It will reduce cost of individualization options and lower the environmental impact of car painting.”

The EcoPaintJet is not only suitable for car bodies, but also for products where paint application has been highly labor-intensive. The range extends from wheels, furniture, two-wheeled vehicles through to cardboard packaging, garage doors and decorations for aircrafts and railway wagons.

The R&D 100 Awards, organized by the US based magazine R&D World, are presented by a diversified jury of experts. Since 1963, the program has identified revolutionary technologies newly introduced to the market and celebrated the top technology products of the year. Past winners have included sophisticated testing equipment, innovative new materials, chemistry breakthroughs, biomedical products, consumer items and high-energy physics spanning industry, academia and government-sponsored research.