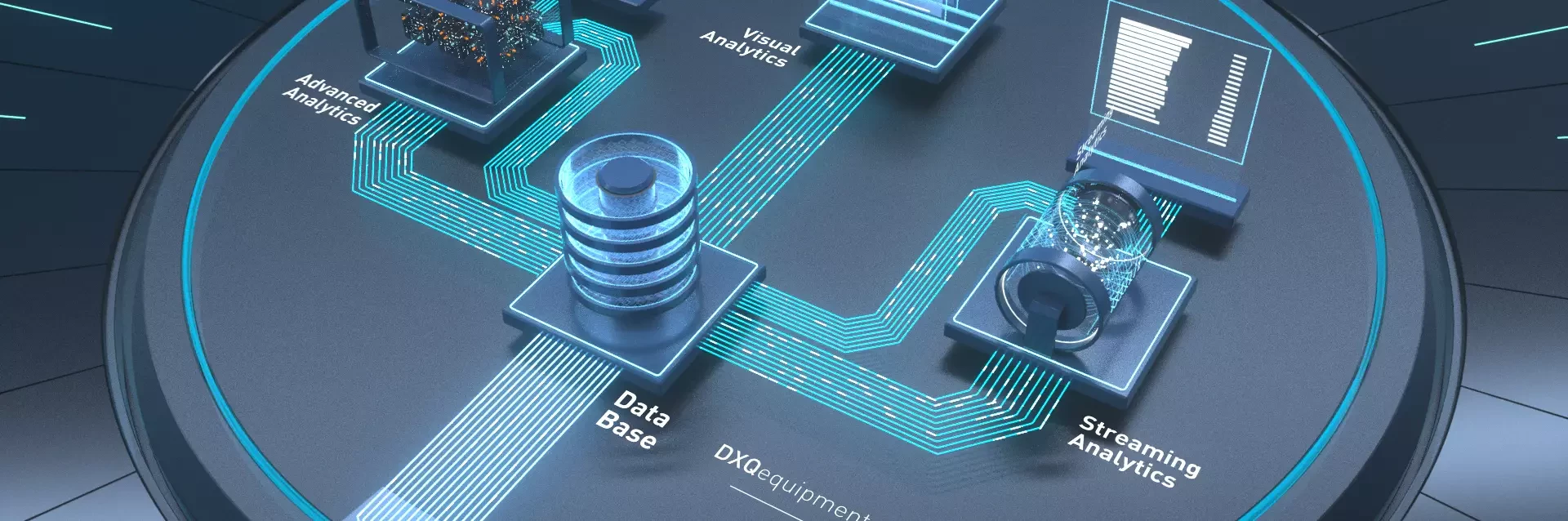

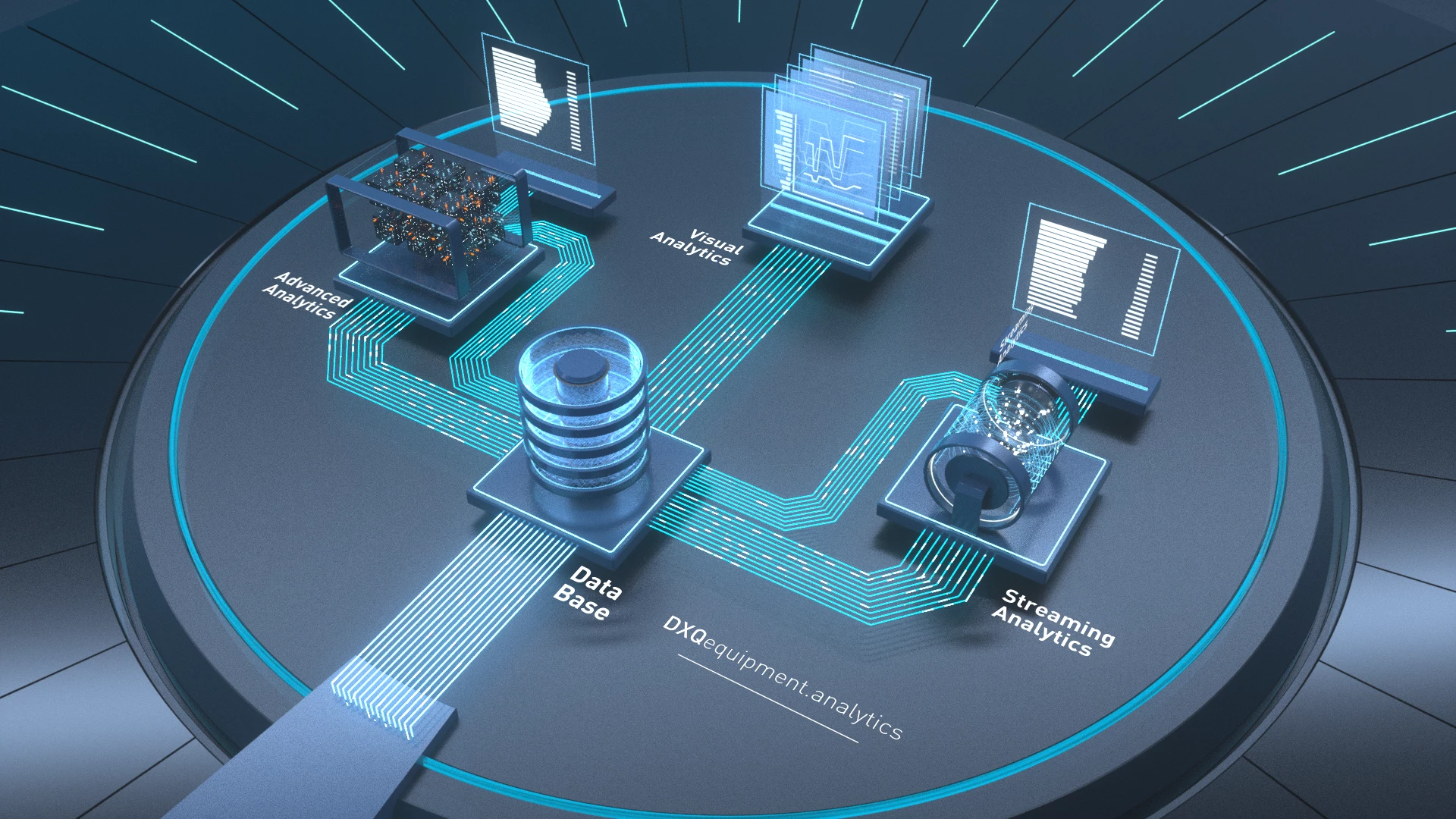

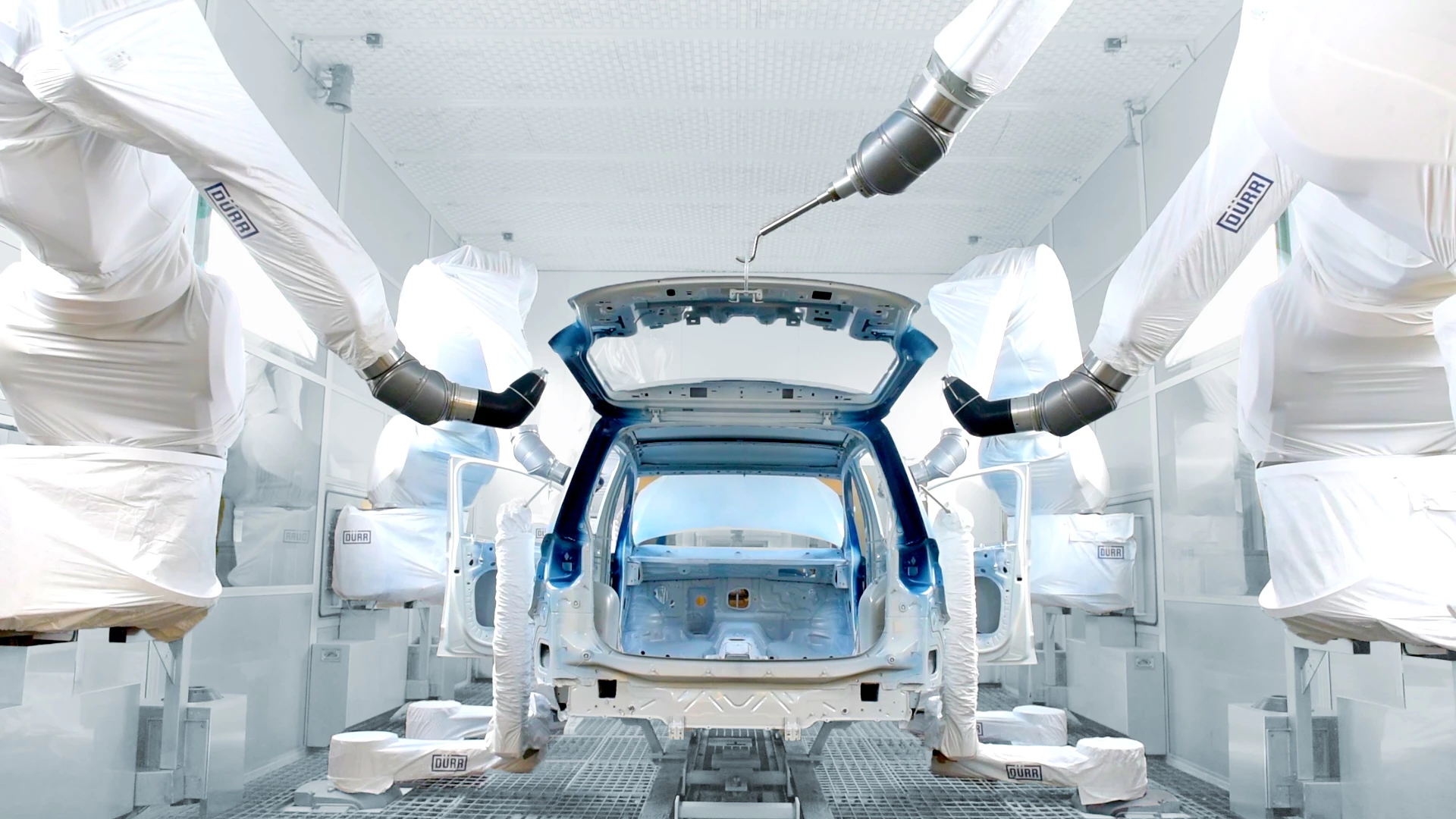

In an initial step, Volkswagen and AWS have opened the Industrial Cloud to eleven partner companies. Dürr contributes a DXQ application, among others, to increase overall equipment effectiveness (OEE). This software is deployed in the quality management of paint shops and uses artificial intelligence (AI) to identify error patterns. To this end, algorithms compare process and order data from different sources. The DXQ application also performs an AI-based status analysis of the painting robots and relates these results to the painting results.

Another Dürr software application in the Industrial Cloud enables productivity en-hancements in final assembly. The DXQ Filling Services application analyzes the system status of filling stations, in which cars can be supplied with fluids such as brake fluid, air-conditioning refrigerant or gear oil. This enables the filling process to be optimized.

Dr. Jochen Weyrauch, CEO of Dürr Systems AG, says: “The integration of partner software in the Industrial Cloud creates a win-win situation. Volkswagen can offer its factories a fast-growing range of diverse software applications. For us, the integration is valuable because it helps us gain new insights into production. This enables us to design our applications in an even more customer-oriented way and better establish them in the market.”

In addition, Dürr is supporting Volkswagen, for example, in digitalizing the new paint shop in the Chinese plant in Anting. This is where DXQ applications for the optimization of processes, production quality, energy consumption and plant maintenance are used. The collaboration with Volkswagen in Anting is Dürr’s largest digitalization project to date.