Factories in the automotive industry have enormous amounts of latent data about manufacturing processes, raw materials and products. The key to leveraging this asset is connectivity – in other words having the right interface at the control level to get at the information provided by robots, ovens, cathodic electrocoating systems or conveyor technology in the first place.

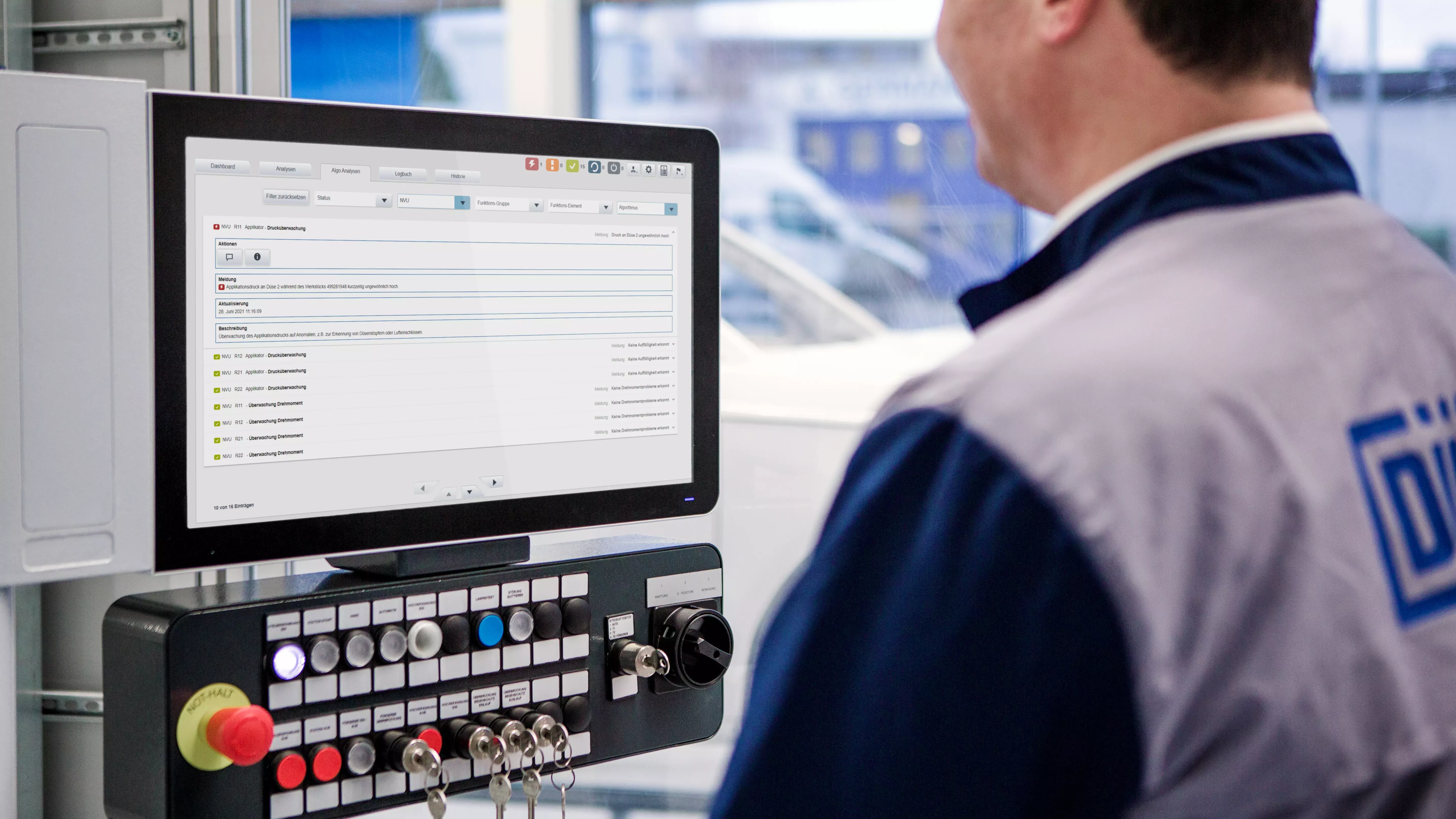

Increasing application quality and plant availability using modern IT technologies involves recording relevant machine data, such as axis positions and temperatures or events like alarms and the start and end times of programs, in real-time and uploading them to a database. “Without this basic prerequisite, software from our DXQ family cannot determine the current state of plant components. The goal is then to combine this with historical data and machine learning to detect previously unknown defect sources or to precisely plan maintenance intervals,” explains Jens Häcker, Vice President Control Systems at Dürr.

Connectivity for existing plants

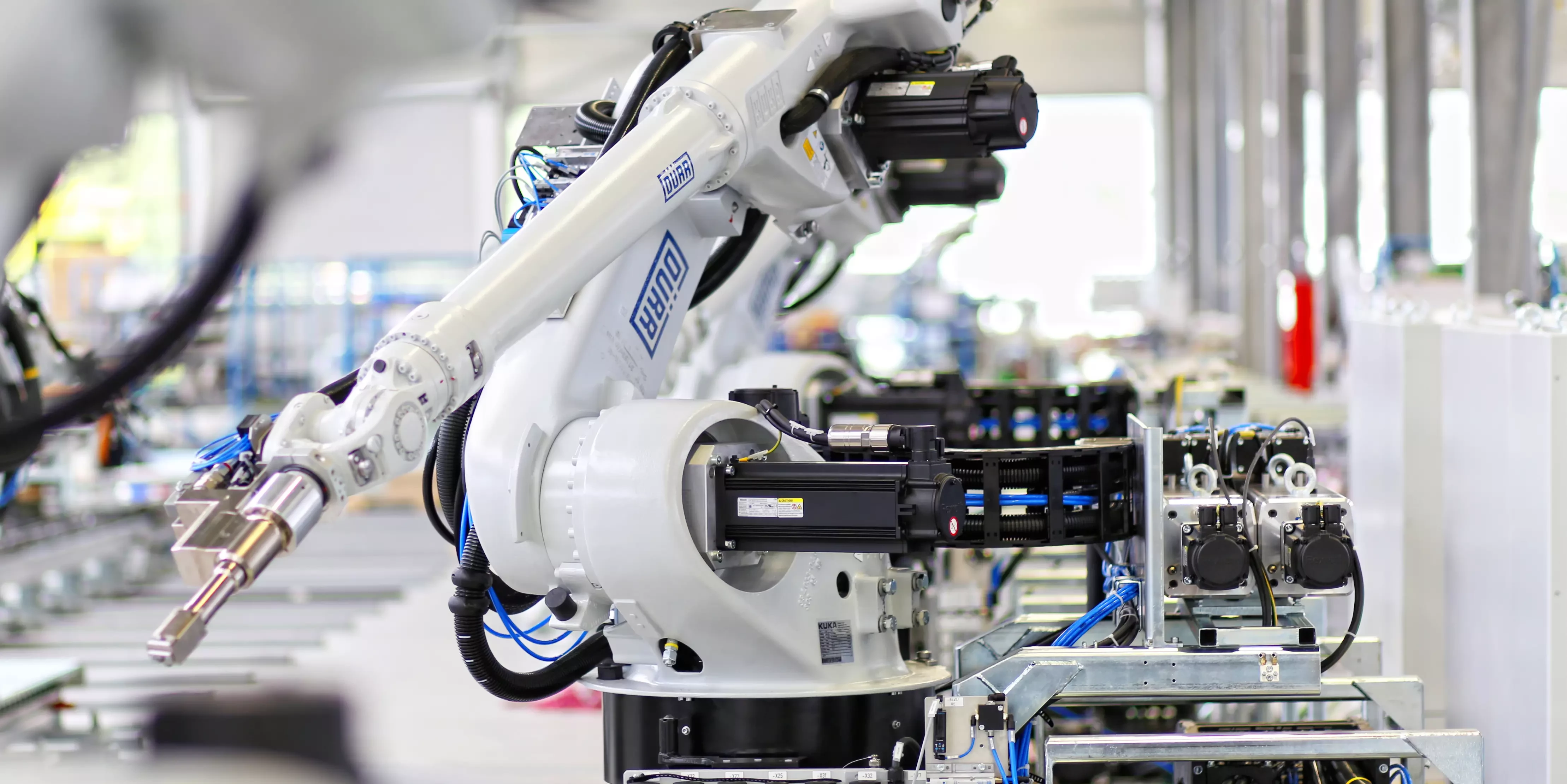

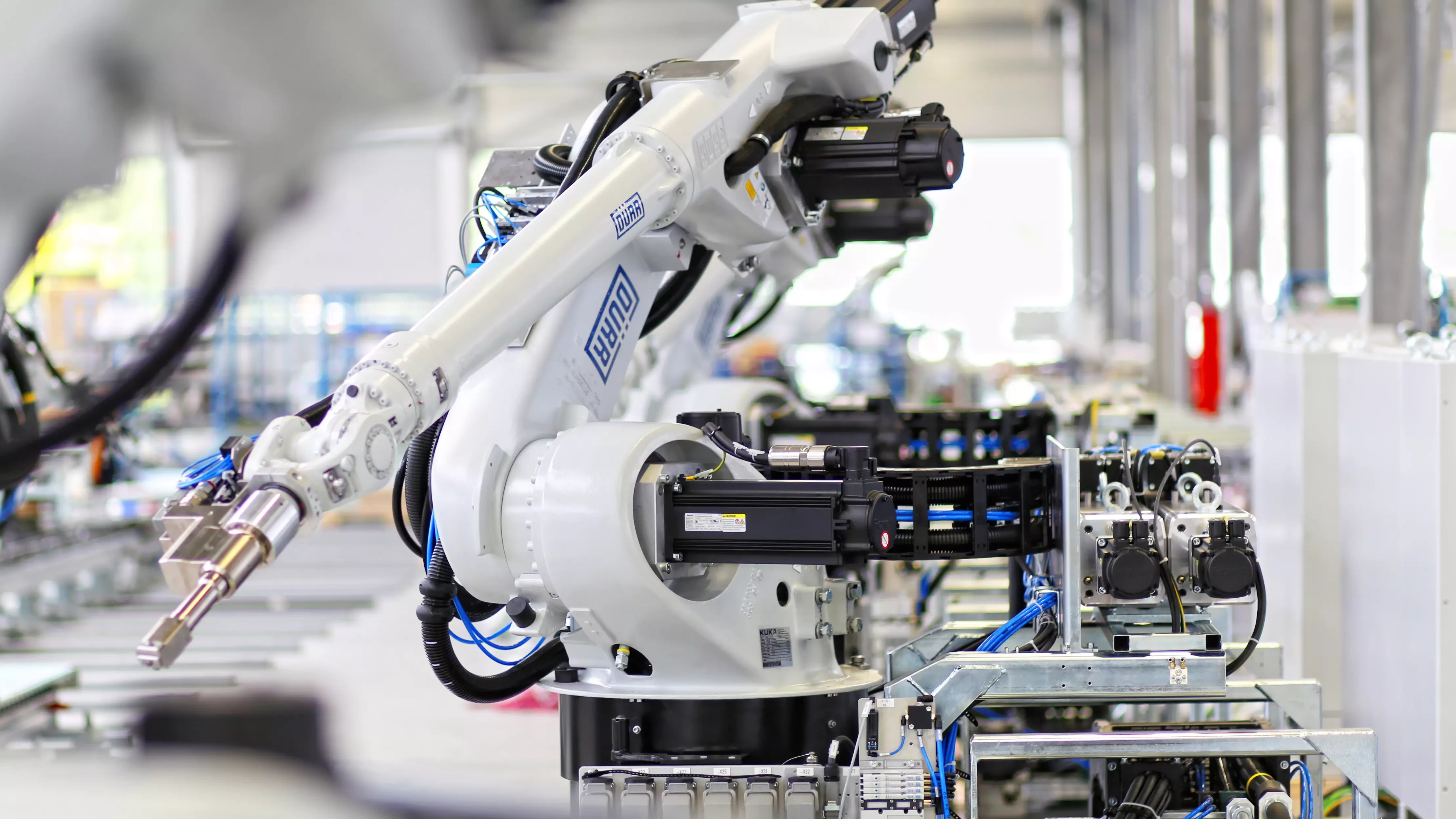

Although the demand for digital applications is high, operators in existing plants are constrained because most of their systems do not have connectivity and the right interface for data acquisition is found only in the later generation of Dürr robots. Previously, earlier models, robots from other manufacturers and technology outside of paint application could not be connected. But Dürr found a way to bring connectivity to almost all common robots and disciplines.

Detailed information from all process steps

The solution is an adapter made up of hardware and software components that can connect to all current fieldbus technologies and that provides data in the necessary high temporal resolution of a few milliseconds. The adapter is offered by Dürr in cooperation with Techno-Step, a specialist in systems for process data analytics and diagnostics that has been part of the Dürr Group since 2020. “Operators are thus able to read the available sensor and actuator data from their existing plants and to integrate the entire spectrum of disciplines, from pretreatment to application to conveyor technology, into one piece of analytical software. With DXQequipment.analytics they get detailed insight into the various process steps and all the systems involved in them along the entire value chain,” says Jens Häcker.

Expertise in mechanical engineering and IT

The DXQequipment.analytics software package includes the Advanced Analytics module. It is the first market-ready solution to date to use artificial intelligence (AI) to increase overall equipment effectiveness in the paint shop. Dürr has expanded this module for sealing by adapting the AI models that analyze the robot and process data for this discipline’s specific requirements. To meet this challenge, Dürr utilized their comprehensive expertise in production technology and manufacturing processes in the automotive industry and a high level of digital knowledge. This combined expertise will make it possible to use AI in the future to precisely detect defect sources at an early stage when applying high-viscosity materials and to determine optimal maintenance schedules. One example is the detection of nozzle clogs. The sealing material partially clogs the application nozzle, changing the material jet and leading to quality defects that require rework to fix. Unlike conventional control technology, the DXQ software detects this defect and enables earlier intervention.