Unifrax’s acquisition of Lauscha Fiber International (now known as USF) expands its inorganic fiber capabilities and reinforces their purpose and vision “Specialty products that save energy, reduce pollution and improve fire safety”. During its long history of producing glass materials, Unifrax specialty fiber has been committed to maintaining the superior glass quality that is essential in the manufacture of high performance glass fibers. The flexibility of their multiple glass furnaces enables Lauscha Fiber to produce a wide range of glass chemistries of outstanding quality for a variety of fiber applications.

With responsible management, good corporate citizenship and a motivated and professional workforce, Lauscha Fiber strives to create sustainable advantages for their customers by providing specialty fibers for a greener, cleaner and safer world.

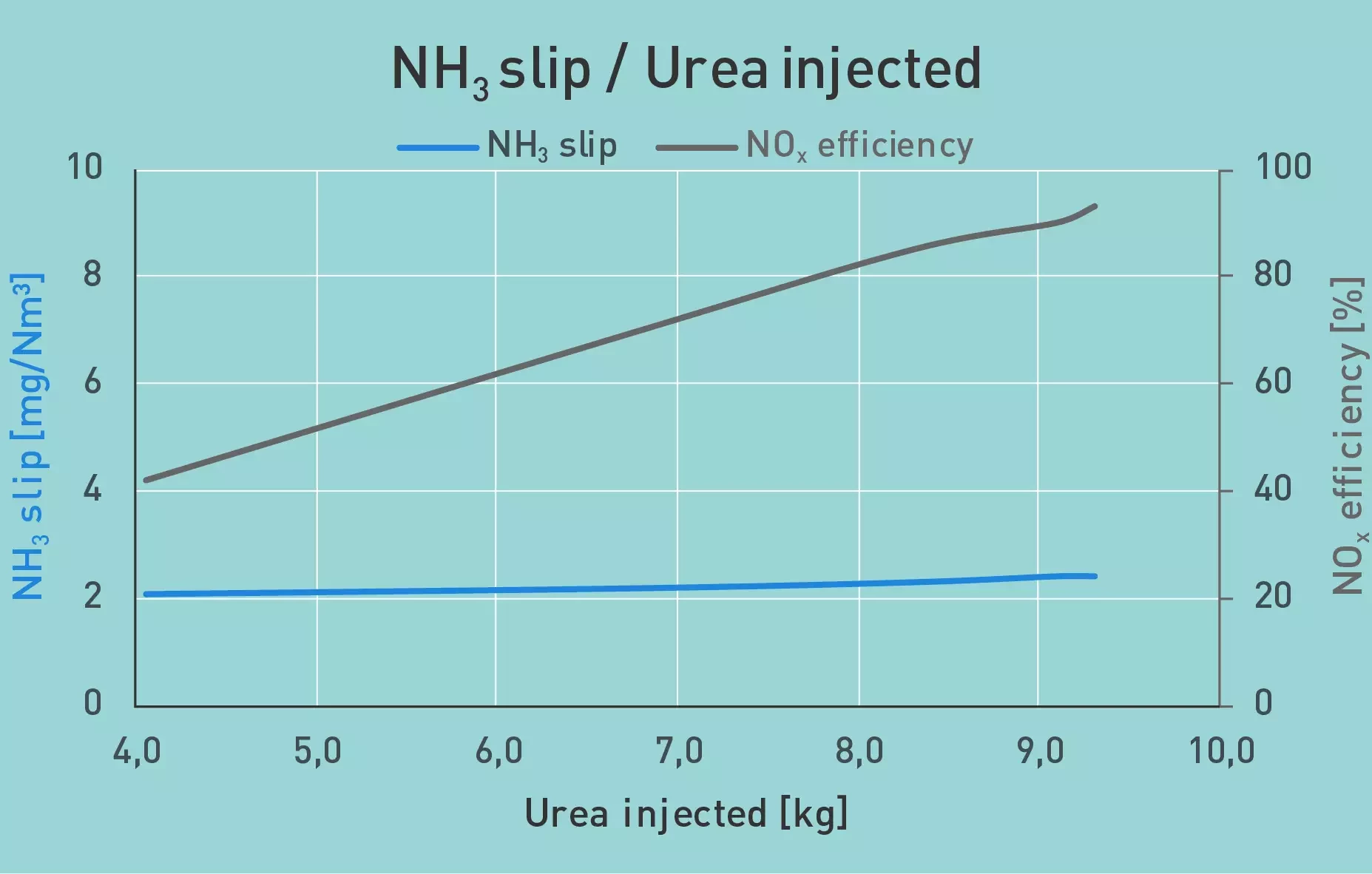

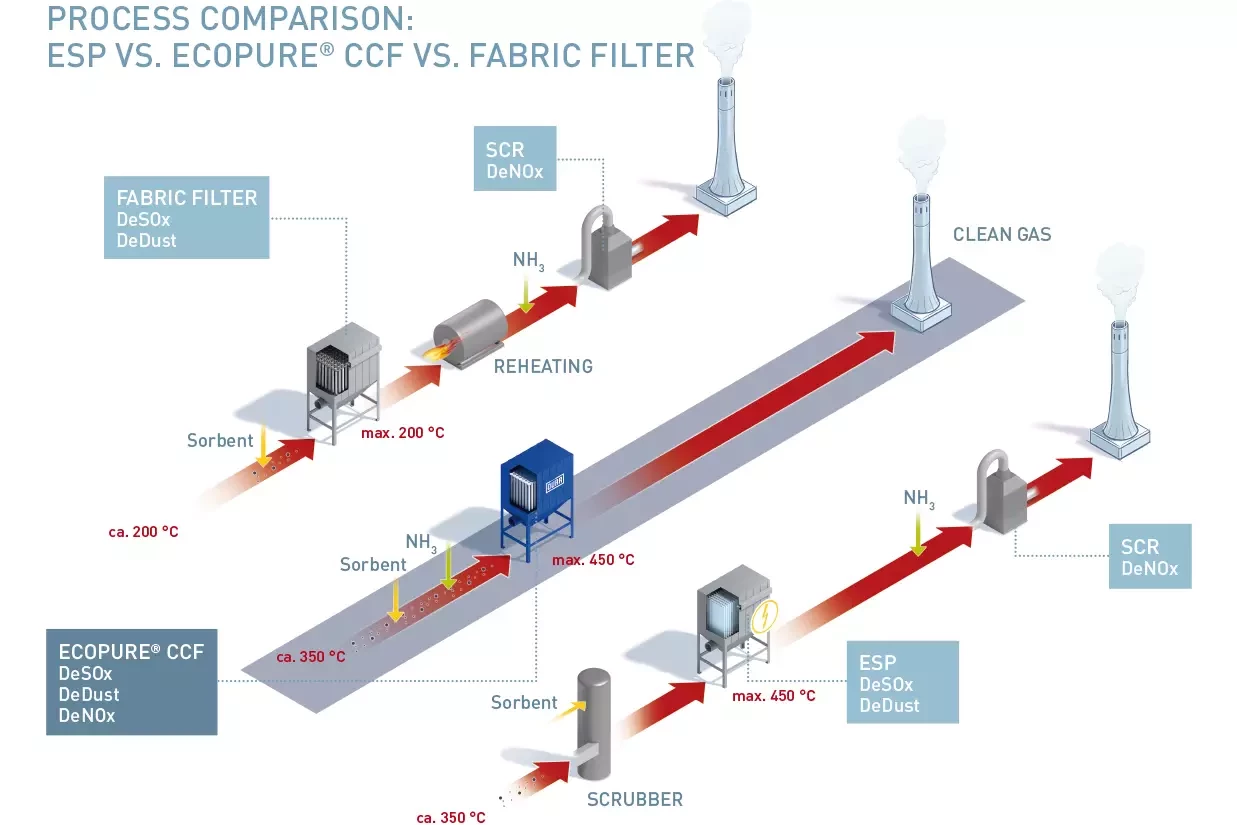

According to their company statement, Robert Greiner, Technical manager of Lauscha Fiber, had to find a proper solution for his emissions. Lauscha Fiber uses two glass furnaces to produce Boron-Silicate Glass which leads to emissions of NOx. Due to the raw material composition, the furnaces emit extremely fine dust, which require a specific system for Air Pollution Control. The High Tech Filter System installed at the Lauscha Fiber location in eastern Germany solves both of these emissions problems.

Legislation and possible solutions

The emission limits for Germany are becoming stricter towards lower allowable concentrations. The “TA-Luft” is under rework, but intermediate regulations have already been set, which require activities in the case of changing or renovating a glass furnace.