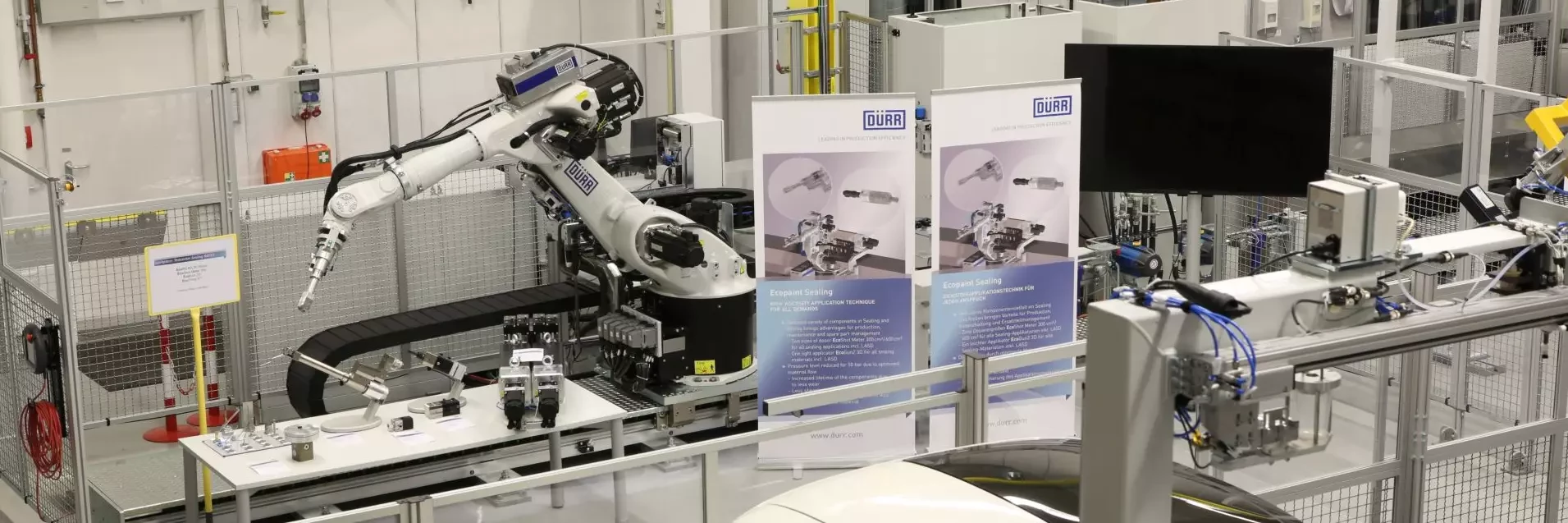

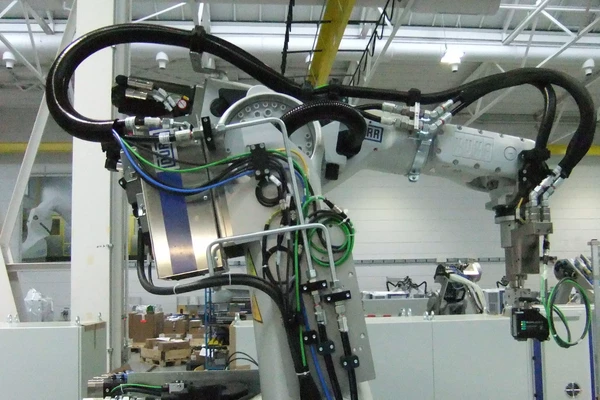

Test center high viscosity application

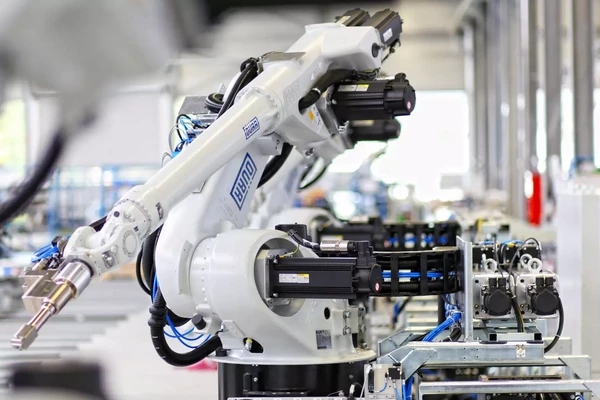

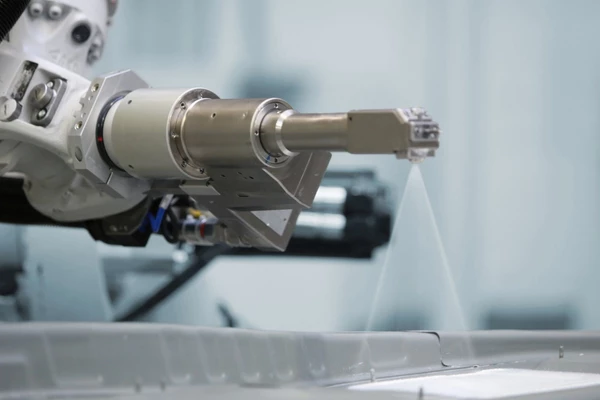

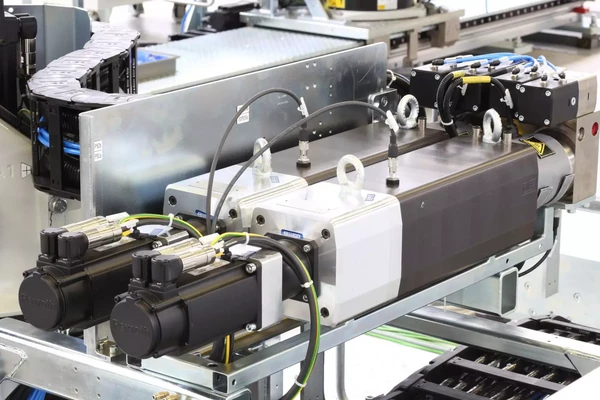

The test center high viscosity application for sealing and gluing applications provides a variety of robots equipped with different dosing systems as well as applicators for all process types.

In the test center high viscosity application, our specialists work on customer-specific solutions at the highest technical level. This gives customers the possibility to conduct tests on sealing applications in order to further develop products and processes for their specific needs and to validate new products. The test center is equipped for all types of processes with its 7-axis sealing robots and robot stations for gluing applications in the body-in-white and final assembly as well as both simple and high-end dispensing systems.

Our service portfolio

- Development and optimization of

- Peripheral components

- New application processes

- Standardization of processes and products

- Validation of processes and products

- Application tests for establishing parameters before putting into service

- Experiments and development on behalf of customers

- Nozzle testing and certification

- Optional: process data monitoring and analysis